Discover why American manufacturers are rapidly adopting AI-driven predictive maintenance to enhance productivity, reduce downtime, lower operational costs, and strengthen industrial competitiveness in 2026 and beyond.

alwepo.com, Across the United States, manufacturing is entering a historic transformation. The pressure to remain globally competitive, boost efficiency, and minimize production losses has pushed factories to embrace digital technologies faster than ever before. Among all innovations reshaping the sector, Artificial Intelligence (AI) stands at the center—particularly in predictive maintenance, a strategy that forecasts equipment failures before they occur.

Predictive maintenance is not new. Manufacturers have long monitored vibrations, temperature, and machine health indicators. But what is new is the intelligence, accuracy, and automation that modern AI brings to industrial equipment monitoring. Using advanced algorithms, machine learning, and real-time data analytics, AI can predict failures with far greater precision than traditional methods—often weeks in advance.

This shift has accelerated dramatically in recent years. According to multiple industrial digitalization trends, American manufacturers are now adopting AI-powered predictive maintenance tools at an unprecedented rate. The reasons are compelling: lower downtime, reduced repair costs, safer operations, and increased production capacity.

This article explores why AI-driven predictive maintenance is booming in the U.S., how it works, the challenges it solves, and what the future of American manufacturing looks like in a world where machines can “tell us” before they break.

1. The Rising Pressure on U.S. Manufacturers

1.1. Global Competition Is Intensifying

American manufacturers face intense competition from countries with lower labor costs and rapidly advancing automation capabilities. China, South Korea, and Germany have invested heavily in Industry 4.0 strategies, pushing the U.S. to accelerate modernization to stay competitive.

AI-driven predictive maintenance gives American factories a significant advantage by:

-

Reducing unplanned downtime

-

Increasing equipment lifespan

-

Minimizing operational waste

-

Improving efficiency without increasing labor

This efficiency modernization is essential for maintaining global competitiveness.

1.2. Unplanned Downtime: A Billion-Dollar Problem

Unplanned downtime is one of the biggest factors affecting manufacturing profitability. In the U.S. industrial sector:

-

Every hour of unexpected downtime can cost $10,000 to $250,000, depending on the industry.

-

Some heavy industries (steel, oil & gas, automotive) report losses exceeding $1 million per hour.

Traditionally, equipment failures are detected after symptoms appear—often too late.

But AI can:

-

Monitor thousands of data points simultaneously

-

Detect microscopic anomalies

-

Predict failures days or weeks earlier

This capability is revolutionary for operations running 24/7.

1.3. Skilled Labor Shortages Are Worsening

Many experienced technicians and maintenance experts are retiring. At the same time, younger generations entering the workforce often lack deep mechanical experience.

AI helps fill the gap by:

-

Automating diagnostics

-

Guiding technicians with actionable insights

-

Reducing dependence on tribal knowledge

-

Ensuring consistent monitoring even with smaller teams

As labor shortages grow, AI becomes a necessity rather than a luxury.

2. What is AI Predictive Maintenance and How Does It Work?

AI-driven predictive maintenance is the use of machine learning, sensor data, and analytics to anticipate when equipment will fail—before breakdowns happen.

It includes several key technologies:

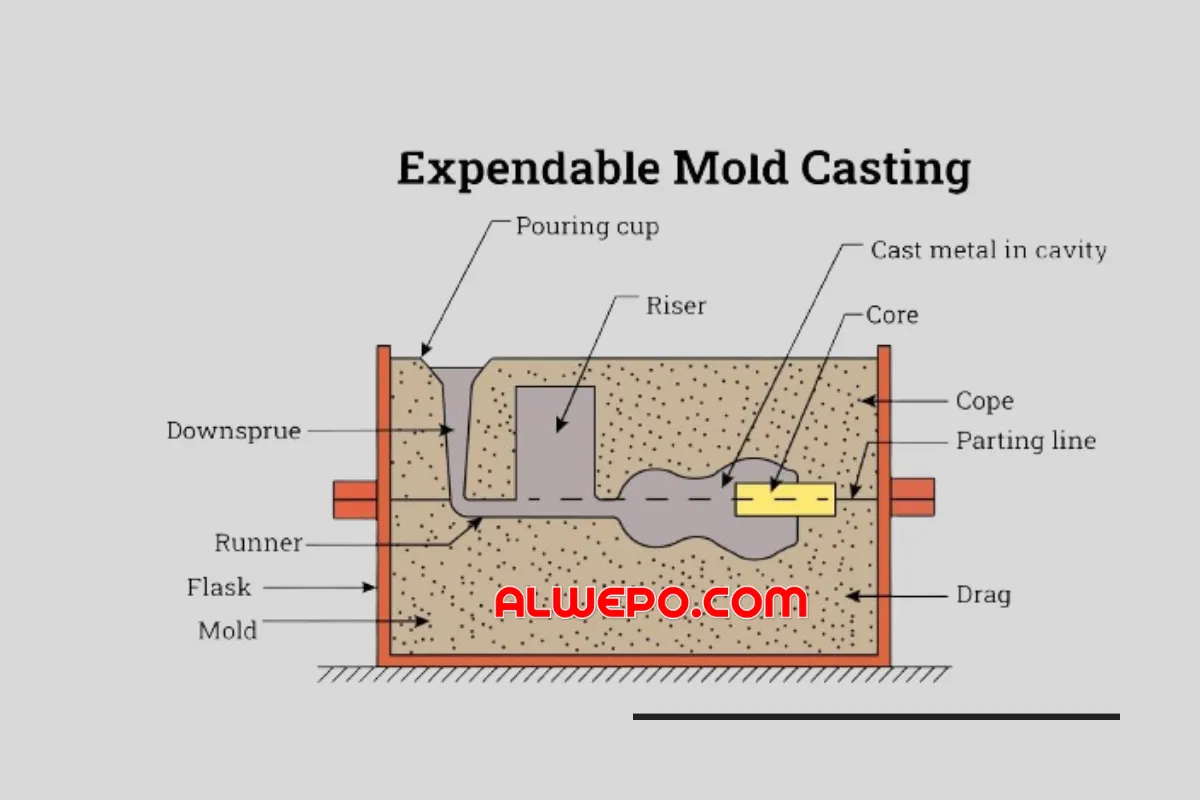

2.1. Sensors and IoT Devices

Modern machines are equipped with sensors that measure:

-

Vibration

-

Temperature

-

Pressure

-

Electrical currents

-

Noise patterns

-

Lubrication quality

-

Motor speed

These sensors feed real-time data into cloud platforms for continuous analysis.

2.2. Machine Learning Algorithms

AI learns from historical and current machine behavior to:

-

Identify early signs of failure

-

Recognize subtle pattern deviations

-

Correlate multiple factors that humans often miss

-

Build predictive models for different equipment types

The more data the system receives, the more accurate the predictions become.

2.3. Digital Twins

Many American manufacturers now use digital twins, which are virtual replicas of machines. These digital models simulate how equipment should behave under various conditions, enabling AI to detect when real performance begins to deviate from the ideal.

2.4. Automated Alerts and Maintenance Scheduling

When the AI system detects an anomaly, it automatically:

-

Sends alerts to maintenance teams

-

Suggests the likely cause of failure

-

Recommends corrective actions

-

Optimizes maintenance schedules

This approach makes maintenance proactive—not reactive.

3. Why U.S. Manufacturers Are Rapidly Adopting AI for Predictive Maintenance

3.1. Significant Cost Savings

Cost reduction is one of the biggest motivators.

AI-driven predictive maintenance helps companies:

-

Reduce downtime by up to 50%

-

Cut maintenance costs by 20–30%

-

Extend machine lifespan by 20%

-

Lower energy consumption

In industries where profit margins are tight, these savings create a massive competitive edge.

3.2. Enhanced Equipment Reliability

Factories depend heavily on consistent uptime. AI ensures machines operate at peak performance by identifying problems early.

Common issues AI can detect include:

-

Bearing failures

-

Misalignments

-

Motor degradation

-

Gearbox wear

-

Lubrication breakdown

-

Overheating

-

Hydraulic system leaks

Predicting these failures early prevents catastrophic breakdowns.

3.3. Improved Worker Safety

Industrial accidents often occur when equipment behaves unpredictably. AI helps prevent:

-

Unexpected mechanical failures

-

Overheating that leads to fires

-

Pressure buildup incidents

-

Equipment explosions

-

Critical electrical failures

By predicting hazards early, AI protects both workers and assets.

3.4. Data-Driven Decision Making

AI gives managers precise insights such as:

-

Which machines are at highest risk

-

When maintenance should be scheduled

-

How machine behavior changes over time

-

Which production lines are most cost-effective

This transforms maintenance from guesswork into a science.

3.5. Sustainability and Energy Efficiency

AI allows manufacturers to optimize:

-

Machine energy usage

-

Waste reduction

-

Resource consumption

-

Carbon emissions

Predictive maintenance prevents energy-wasting conditions, such as friction or misalignment.

4. Real-World Applications by U.S. Manufacturers

4.1. Automotive Manufacturing

Companies like Ford and GM are using AI to:

-

Monitor robots on assembly lines

-

Predict motor and conveyor failures

-

Reduce welding machine downtime

This ensures uninterrupted mass production.

4.2. Aerospace and Defense

In aerospace, predictive maintenance is essential for safety. AI helps monitor:

-

Jet engine components

-

Turbine blades

-

Hydraulic systems

-

Composite materials

This ensures compliance with strict safety regulations.

4.3. Food and Beverage Manufacturing

AI prevents contamination risks by monitoring:

-

Temperature control systems

-

Packaging equipment

-

Conveyors

-

Refrigeration units

Avoiding downtime is crucial for perishable goods.

4.4. Energy and Oil & Gas

AI helps manage:

-

Pumps

-

Valves

-

Compressors

-

Pipelines

Predictive maintenance reduces environmental risks and operational disruptions.

5. The Economic Impact: Why the U.S. is Betting Big on AI

5.1. A Catalyst for American Manufacturing Reshoring

Predictive maintenance plays a key role in reshoring efforts, making U.S. factories more efficient and cost-competitive, encouraging companies to bring production back home.

5.2. Higher Production Output

With fewer breakdowns, factories can:

-

Increase throughput

-

Run longer shifts

-

Meet customer demand faster

-

Minimize bottlenecks

This boosts profitability and growth.

5.3. Improved Asset ROI

Manufacturers maximize the value of expensive machinery by extending its useful life and reducing costly repairs.

6. Challenges in AI Predictive Maintenance Adoption

While adoption is growing rapidly, manufacturers face some obstacles:

6.1. Upfront Costs

Sensors, cloud integration, and training require investment. However, the long-term ROI makes AI adoption worthwhile.

6.2. Cultural Resistance

Some technicians are hesitant to trust automated systems. Training and change management are essential.

6.3. Data Integration Issues

Factories use machines from various brands and decades. Integrating these systems into a unified AI platform can be challenging.

6.4. Cybersecurity Concerns

More connected systems mean manufacturers must strengthen digital security to protect industrial networks.

7. The Future: What AI Predictive Maintenance Means for American Factories

7.1. Autonomous Maintenance

Future AI systems will not only predict failures—they will eventually:

-

Self-adjust machine settings

-

Auto-calibrate sensors

-

Initiate repair sequences

-

Order replacement parts automatically

This marks the beginning of fully autonomous factories.

7.2. AI + Robotics Integration

Maintenance robots will work alongside AI to conduct inspections, lubrication, and minor repairs without human intervention.

7.3. Predictive Supply Chain Synchronization

AI will predict spare part requirements and coordinate with suppliers in real-time. This eliminates downtime caused by parts shortages.

7.4. Industry-Specific AI Models

Manufacturers will deploy specialized AI systems designed for:

-

Metal processing

-

Chemical plants

-

Pharmaceutical manufacturing

-

Semiconductor production

-

Heavy machinery manufacturing

These tailored solutions deliver even greater accuracy.

Conclusion: Why AI Predictive Maintenance Has Become a U.S. Manufacturing Priority

American manufacturers are adopting AI for predictive maintenance at unprecedented speed because it directly solves their biggest challenges—downtime, labor shortages, high maintenance costs, and global competition.

By using AI, factories can:

-

Predict failures before they happen

-

Improve operational safety

-

Cut costs and increase efficiency

-

Extend machine life

-

Make smarter data-driven decisions

As the industry continues to evolve, AI-driven predictive maintenance will become a standard requirement for any factory hoping to stay competitive in the next decade.

.jpg)

Leave a Reply

View Comments