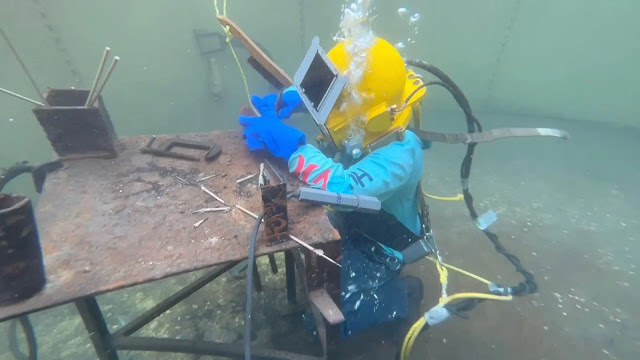

Hello Alwepo friends, in this article, we will delve into the important topic of the underwater welder fatality rate. Underwater welding is a unique and challenging profession that combines welding skills with diving expertise. While it offers exciting opportunities and lucrative compensation, it’s essential to understand the risks and safety concerns associated with this occupation. By exploring the underwater welder fatality rate and the factors contributing to it, we aim to shed light on the safety aspects of this fascinating field.

Understanding the Nature of Underwater Welding

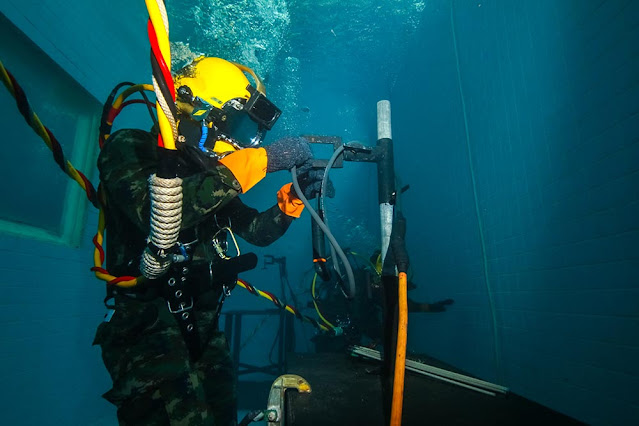

Underwater welding involves performing welding tasks in an underwater environment. This specialized field requires individuals with a combination of welding expertise and diving skills. Underwater welders play a crucial role in various industries, including oil and gas, construction, and marine services. They are responsible for welding and repairing structures such as pipelines, offshore platforms, ships, and underwater installations.

The Demand for Underwater Welders

The demand for underwater welders is driven by the ongoing need for maintenance, repair, and construction of underwater structures. Industries such as offshore oil and gas exploration, marine infrastructure development, and underwater salvage operations heavily rely on the expertise of underwater welders. As the world’s population continues to grow, the demand for energy and resources increases, further driving the need for skilled professionals in this field.

The Unique Challenges of Underwater Welding

Underwater welding presents unique challenges that set it apart from traditional welding. Working in an underwater environment introduces various complexities and risks. Underwater welders must navigate limited visibility, extreme temperatures, high water pressure, and hazardous marine life. Additionally, they face time constraints due to limited diving durations and the need to manage welding tasks efficiently.

Factors Influencing Fatality Rate in Underwater Welding

Understanding the factors contributing to the underwater welder fatality rate is crucial for improving safety in the profession. Several factors influence the risk of fatalities in underwater welding:

1. Hazardous Underwater Environment

Underwater welders operate in a challenging environment that poses numerous risks. They must contend with strong currents, unpredictable weather conditions, and potential exposure to toxic substances.

2. Diving Risks and Complications

Diving itself carries inherent risks, including decompression sickness, nitrogen narcosis, and oxygen toxicity. These risks can be exacerbated by the physical demands of welding tasks and the need to maintain proper buoyancy control.

3. Welding Hazards in Underwater Conditions

Underwater welding introduces additional hazards compared to welding in a controlled environment. The presence of water can affect the stability of the electric arc, and hydrogen bubbles can form during the welding process, potentially leading to weld defects.

4. Limited Visibility and Communication

Poor visibility in underwater conditions makes it challenging to identify potential hazards and communicate effectively with team members. This limitation increases the risk of accidents and delays in responding to emergencies.

5. Time Constraints and Stressful Working Conditions

Underwater welders often face tight deadlines to complete their tasks. The pressure to work efficiently within limited diving durations can lead to increased stress levels and potential compromises in safety procedures.

Statistical Analysis: Underwater Welder Fatality Rate

Accurate data collection and analysis are vital for understanding the underwater welder fatality rate and identifying trends. While precise statistics on fatalities in underwater welding are not readily available, efforts have been made to analyze available data and establish an understanding of the risks involved.

Data suggests that the fatality rate in underwater welding is relatively higher compared to other occupations. Factors contributing to this include the inherent risks of working in an underwater environment, the complexity of welding tasks, and the need to integrate diving and welding skills effectively.

Comparing the underwater welder fatality rate with other professions highlights the need for continuous improvement in safety practices and training. By understanding the statistics, the industry can identify areas of concern and implement measures to mitigate risks and prevent accidents.

Contributing Factors to Underwater Welder Fatalities

To address the issue of underwater welder fatalities, it’s essential to examine the contributing factors:

1. Inadequate Training and Experience

Insufficient training and experience can significantly increase the risk of accidents. Underwater welders must undergo comprehensive training programs that cover both diving and welding skills to ensure they are well-prepared for the challenges they will encounter.

2. Lack of Proper Safety Procedures

Failure to follow established safety procedures can have severe consequences. Strict adherence to safety protocols, such as pre-dive safety briefings, equipment inspections, and emergency response planning, is critical for minimizing risks.

3. Equipment Failure and Malfunction

Equipment failure can lead to accidents and injuries in underwater welding. Regular maintenance, inspection, and the use of reliable equipment are essential to prevent malfunctions that could jeopardize the safety of underwater welders.

4. Medical Emergencies and Diving Accidents

Medical emergencies, such as decompression sickness or other diving-related injuries, can occur during underwater welding operations. Proper emergency response protocols and access to medical facilities are essential for addressing such situations promptly.

5. Human Error and Poor Decision-Making

Human error, whether due to fatigue, complacency, or poor judgment, can significantly impact safety. Promoting a culture of accountability, emphasizing the importance of adherence to procedures, and continuous training can help mitigate human error.

Mitigating Risks and Enhancing Safety Protocols

Reducing the underwater welder fatality rate requires a concerted effort from various stakeholders. To enhance safety in underwater welding, the following measures should be considered:

- Implementing Rigorous Training Programs: Comprehensive training programs should be developed to equip aspiring underwater welders with the necessary skills and knowledge. This training should cover both diving and welding techniques, safety procedures, and emergency response protocols.

- Promoting Industry Standards and Regulations: Establishing and enforcing industry standards and regulations is crucial for ensuring uniform safety practices across the profession. Regulatory bodies, industry associations, and employers should collaborate to develop and uphold these standards.

- Advancements in Diving and Welding Technology: Technological advancements play a significant role in improving safety in underwater welding. Innovations in diving equipment, welding techniques, and remote monitoring systems can enhance both the efficiency and safety of underwater welding operations.

- Conducting Risk Assessments and Job Hazard Analyses: Thorough risk assessments and job hazard analyses should be conducted before commencing underwater welding projects. Identifying potential hazards and implementing appropriate controls can significantly reduce the risk of accidents.

- Fostering a Culture of Safety and Accountability: Creating a culture that prioritizes safety and encourages open communication is essential. All stakeholders, including employers, employees, and regulatory bodies, should work together to foster a sense of accountability for safety.

Safety Measures for Underwater Welders

To ensure the safety of underwater welders, the following safety measures should be implemented:

- Proper Diving Training and Certification: Underwater welders should undergo extensive training and obtain the necessary certifications, such as commercial diving certifications and welding qualifications.

- Utilizing Appropriate Personal Protective Equipment (PPE): Underwater welders must use the appropriate PPE, including diving suits, helmets, gloves, and welding masks, to protect themselves from potential hazards.

- Pre-Dive Safety Briefings and Planning: Before each dive, a thorough safety briefing should be conducted to ensure all team members are aware of the specific hazards and safety procedures associated with the task at hand.

- Regular Equipment Maintenance and Inspection: Regular maintenance and inspection of diving and welding equipment are essential to identify any potential issues or malfunctions before they compromise safety.

- Emergency Response and First Aid Preparedness: Adequate emergency response protocols, including the availability of trained personnel and well-equipped first aid kits, should be in place to address any medical emergencies or diving accidents promptly.

Collaborative Efforts: Industry and Government Initiatives

To address the issue of underwater welder fatalities effectively, collaboration between industry stakeholders and government bodies is crucial. The following initiatives can help improve safety:

- Collaboration between Diving and Welding Associations: Diving and welding associations should work together to develop comprehensive guidelines and best practices that prioritize safety in underwater welding operations.

- Government Regulations and Oversight: Governments should establish and enforce regulations that outline safety standards for underwater welding. Regular inspections and audits can ensure compliance with these regulations.

- Research and Development for Safety Innovations: Investment in research and development can lead to the discovery of innovative solutions to enhance safety in underwater welding. This includes advancements in equipment, training techniques, and safety protocols.

- Sharing Best Practices and Lessons Learned: Sharing best practices and lessons learned from past incidents is vital for the industry’s continuous improvement. Collaborative platforms and industry conferences should facilitate the exchange of knowledge and experiences.

- Promoting a Supportive Safety Culture in the Workplace: Employers should foster a safety culture that encourages employees to report safety concerns and near-misses without fear of retribution. Regular safety meetings and training sessions can help reinforce the importance of safety.

Real-Life Case Studies: Learning from Past Incidents

Analyzing real-life case studies can provide valuable insights into the factors contributing to underwater welder fatalities and help identify preventive measures:

- Case Study 1: The Consequences of Inadequate Training: A case study examining an incident caused by insufficient training can highlight the importance of comprehensive training programs and the risks associated with inexperienced underwater welders.

- Case Study 2: Equipment Failure and Fatalities: This case study focuses on an incident resulting from equipment failure, emphasizing the need for regular maintenance, inspection, and the use of reliable equipment.

- Case Study 3: Importance of Emergency Response Planning: Examining an incident where an effective emergency response saved lives highlights the significance of thorough emergency planning and preparedness.

- Case Study 4: Lessons from Successful Safety Programs: This case study showcases examples of companies with successful safety programs, demonstrating the positive impact of prioritizing safety and implementing effective safety measures.

- Case Study 5: Addressing Human Factors in Fatality Prevention: Analyzing a case study involving human error and poor decision-making can shed light on the importance of human factors training, fatigue management, and promoting a culture of accountability.

Mental Health and Well-Being of Underwater Welders

While addressing physical safety is crucial, it’s also essential to consider the mental health and well-being of underwater welders:

- Understanding the Psychological Challenges: The unique working conditions and demands of underwater welding can take a toll on the mental health of individuals in the profession. Factors such as isolation, high-pressure environments, and the potential for traumatic incidents can contribute to stress, anxiety, and other mental health challenges.

- The Importance of Mental Health Support: Employers should prioritize mental health support for underwater welders. Providing access to counseling services, promoting work-life balance, and creating supportive work environments can help alleviate mental health issues.

- Promoting Work-Life Balance and Stress Management: Encouraging work-life balance through appropriate scheduling, time off, and stress management techniques can help underwater welders maintain their well-being and overall job satisfaction.

- Encouraging Open Communication and Peer Support: Creating avenues for open communication, such as regular team meetings and mentoring programs, can foster a sense of camaraderie and provide support for underwater welders facing challenges.

- Raising Awareness and Eliminating Stigma: Promoting awareness about mental health challenges and eliminating stigma within the industry can encourage individuals to seek help when needed. Education and training programs should be implemented to increase awareness and provide resources for mental health support.

The Way Forward: Striving for Zero Fatalities

To achieve a future with zero fatalities in underwater welding, the industry must commit to continuous improvement and collaborative efforts:

- Continuous Improvement and Learning: Regular evaluation of safety practices, learning from incidents, and implementing lessons learned are essential for continuous improvement in safety standards.

- Emphasizing Safety Culture in Training Programs: Safety culture should be ingrained in training programs for underwater welders, emphasizing the importance of following procedures, reporting hazards, and maintaining accountability.

- Encouraging Reporting and Incident Investigation: Establishing a culture that encourages reporting of near-misses, incidents, and hazards is vital for proactive identification and resolution of safety issues. Thorough incident investigations help identify root causes and prevent future occurrences.

- Industry Collaboration and Knowledge Sharing: Collaboration between industry stakeholders, including diving associations, welding organizations, employers, and regulatory bodies, is crucial for sharing best practices, addressing common challenges, and working together to enhance safety.

- The Role of Underwater Welders in Safety Advocacy: Underwater welders themselves can play a significant role in safety advocacy. By actively participating in safety programs, sharing their experiences, and promoting best practices, they can contribute to a safer working environment for all.

Conclusion: Ensuring Safety in Underwater Welding

Thus, the article about underwater welder fatality rate sheds light on the safety aspects of this challenging profession. By understanding the factors influencing the fatality rate, analyzing statistics, and exploring safety measures, we can work towards mitigating risks and creating a safer working environment for underwater welders. It is crucial to prioritize comprehensive training, strict adherence to safety protocols, and continuous improvement in the industry. Together, we can strive towards a future with zero fatalities in underwater welding. Feel free to share your thoughts and continue the discussion in the comments section, don’t forget to share the article with your friends or your favorite social media. Hope it is useful!

.webp)