Learn essential Top Tips for Heavy Equipment Operation Safety in this comprehensive and unique article. Discover the importance of safety, proper equipment familiarization, safe loading and unloading practices, and much more. Stay informed and prioritize safety to prevent accidents and injuries while operating heavy machinery. Don’t miss this valuable guide for a safer and more productive worksite.

Hello Alwepo friends, in this article we will discuss Top Tips for Heavy Equipment Operation Safety. Operating heavy equipment comes with its own set of risks and hazards. It is crucial for operators to prioritize safety to prevent accidents and injuries. In this comprehensive guide, we will provide you with essential tips and guidelines to ensure safe operation of heavy equipment. So, let’s dive in and explore the top tips for heavy equipment operation safety!

Heavy Equipment Operation

Heavy equipment operation involves the use of various machinery and vehicles to perform tasks such as excavation, material handling, construction, and transportation. It is a critical component of many industries, including construction, mining, agriculture, and manufacturing. The operation of heavy equipment requires specialized skills, knowledge, and adherence to safety protocols to prevent accidents and protect both the operators and those working in the vicinity.

The Importance of Safety in Heavy Equipment Operation

Safety should always be the top priority when operating heavy equipment. Accidents involving heavy machinery can lead to severe injuries, fatalities, property damage, and costly downtime. Prioritizing safety not only protects the well-being of operators and workers but also contributes to the overall productivity and efficiency of the worksite. By following proper safety procedures and adopting a safety-first mindset, operators can minimize risks and create a safer working environment.

Understanding the Types of Heavy Equipment

Before delving into safety tips, it is essential to have a basic understanding of the types of heavy equipment commonly used in various industries. The following are some examples of heavy equipment:

- Excavators

- Bulldozers

- Loaders

- Cranes

- Forklifts

- Graders

- Dump Trucks

- Backhoes

- Pavers

- Compactors

Each type of heavy equipment has its unique features, capabilities, and safety considerations. Operators must be familiar with the equipment they are operating and follow manufacturer guidelines and recommendations for safe operation.

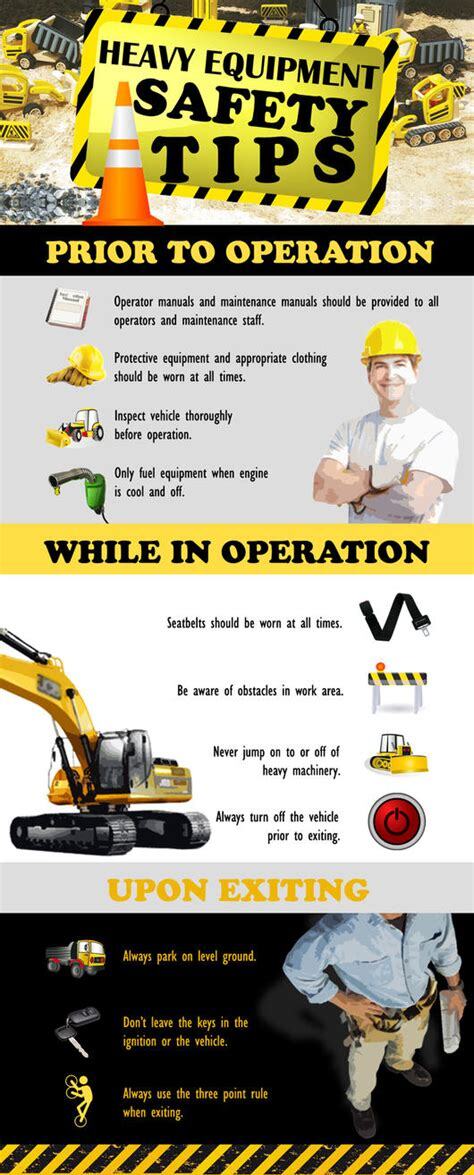

Pre-Operation Safety Checks

1. Inspecting the Equipment

Before starting any heavy equipment, it is crucial to perform a thorough inspection to ensure it is in proper working condition. Here are some key components to check:

- Fluid levels: Check the levels of fuel, oil, hydraulic fluid, and coolant.

- Tires or tracks: Inspect for damage, wear, and proper inflation.

- Brakes: Test the brakes for responsiveness and effectiveness.

- Lights and signals: Ensure all lights and signals are functional.

- Safety features: Check for the presence and functionality of safety devices such as seat belts, backup alarms, and fire extinguishers.

2. Checking Safety Devices

Heavy equipment is equipped with various safety devices to protect operators and others on the worksite. Before operation, verify the following:

- Seat belts: Ensure seat belts are present and in good condition. Always wear them while operating the equipment.

- Rollover protective structures (ROPS) and falling object protective structures (FOPS): Check for the presence and integrity of these structures.

- Backup alarms: Ensure backup alarms are audible and functioning correctly.

- Mirrors and cameras: Adjust mirrors and test cameras for clear visibility around the equipment.

Personal Protective Equipment (PPE)

When operating heavy equipment, wearing appropriate personal protective equipment (PPE) is essential to protect against potential hazards. The following are some common PPE items for heavy equipment operators:

- Hard hat: Protects the head from falling objects and overhead hazards.

- Safety goggles: Shields the eyes from debris, dust, and other flying particles.

- High-visibility vest: Increases visibility to others on the worksite, reducing the risk of collisions.

- Steel-toed boots: Provides foot protection from heavy objects and crushing hazards.

- Gloves: Protects the hands from cuts, abrasions, and hand-arm vibration syndrome (HAVS).

- Ear protection: Reduces exposure to high noise levels, preventing hearing damage.

Always wear the appropriate PPE specified for the equipment being operated and the tasks involved.

Safe Operating Procedures

Operating heavy equipment requires adherence to safe procedures to minimize the risk of accidents. Let’s explore some top tips for safe operation:

1. Proper Equipment Familiarization

Before operating any heavy equipment, operators should receive comprehensive training on the specific machinery they will be using. Familiarize yourself with the equipment’s controls, functions, and safety features. Training should include hands-on practice and guidance from experienced operators or trainers.

2. Clear Communication

Effective communication is crucial on construction sites and in areas where heavy equipment is operating. Operators should use hand signals, radios, or other communication tools to coordinate movements with other workers and equipment operators. Establishing clear communication protocols helps prevent accidents and misunderstandings.

3. Maintaining a Safe Distance

Keep a safe distance from other equipment, workers, and obstacles while operating heavy machinery. Avoid operating too close to edges, slopes, or unstable surfaces. Maintaining distance helps reduce the risk of collisions and accidents.

4. Avoiding Distractions

Operating heavy equipment requires full attention. Avoid distractions such as using mobile phones, listening to loud music, or engaging in non-work-related conversations while operating the equipment. Focus on the task at hand to prevent accidents.

5. Operating in Optimal Conditions

Heavy equipment performs best under certain weather and ground conditions. Avoid operating in severe weather conditions such as heavy rain, snow, or strong winds. Additionally, be cautious in low-light conditions, as visibility may be reduced.

Safe Loading and Unloading Practices

1. Understanding Load Capacities

Each piece of heavy equipment has a specific load capacity. Exceeding this capacity can lead to instability and tipping. Always know the load capacity of the equipment and avoid overloading.

2. Securing the Load

Before transporting materials, ensure the load is properly secured using appropriate tie-downs, chains, or straps. A loose load can shift during travel, leading to a loss of control.

3. Proper Loading and Unloading Techniques

Follow proper loading and unloading procedures to prevent accidents and injuries. Use loading ramps, designated loading areas, and avoid sudden movements during loading and unloading processes.

Safe Maneuvering and Traveling

1. Maintaining Stability

Ensure the equipment is on stable ground before operating. Avoid steep inclines or uneven terrain that could cause the equipment to tip over.

2. Observe Speed Limits

Follow recommended speed limits for the specific equipment and worksite conditions. Excessive speed can compromise control and lead to accidents.

3. Adapting to Terrain

Different terrains require different operating techniques. Adjust your approach based on the ground conditions to maintain control and stability.

4. Avoiding Obstacles

Keep a lookout for obstacles such as rocks, tree stumps, or utility lines that could interfere with the equipment’s movements.

5. Backing Up Safely

Use caution when backing up heavy equipment. Check mirrors and use spotters when necessary to ensure there are no obstacles or workers in the blind spots.

Safe Maintenance and Repairs

1. Regular Inspections

Implement a routine inspection schedule to identify and address potential issues before they become major problems. Regular inspections can prevent breakdowns and accidents caused by equipment malfunctions.

2. Proper Lockout/Tagout Procedures

During maintenance or repairs, follow lockout/tagout procedures to isolate and secure the equipment’s energy sources. This prevents accidental startups and protects maintenance personnel.

3. Qualified Mechanics

Ensure that only qualified and trained mechanics perform repairs and maintenance on heavy equipment. Hiring professionals minimizes the risk of errors and ensures the work is completed to industry standards.

Emergency Preparedness

1. Emergency Response Plans

Develop and implement emergency response plans for potential accidents or incidents. Ensure all workers are familiar with the procedures and know the location of emergency equipment.

2. Emergency Equipment and First Aid

Keep first aid kits and emergency equipment readily accessible on the worksite. In the event of an injury, prompt medical attention can make a significant difference in the outcome.

Operator Training and Certification

Comprehensive Training

Invest in comprehensive training programs for heavy equipment operators. Certification courses provide operators with the necessary skills and knowledge to operate safely and efficiently.

Promoting a Safety Culture

1. Safety Meetings and Toolbox Talks

Hold regular safety meetings and toolbox talks to discuss safety issues, share best practices, and address any concerns raised by the team.

2. Reporting Near Misses and Incidents

Encourage workers to report near misses and incidents, even if no injuries or damages occurred. Learning from near misses helps prevent future accidents.

3. Recognizing and Rewarding Safe Practices

Recognize and reward individuals or teams that consistently demonstrate safe operating practices. Positive reinforcement fosters a safety-conscious culture.

4. Continuous Improvement

Continuously review and improve safety protocols, procedures, and equipment. Staying updated on best practices ensures a safer working environment.

Conclusion

Operating heavy equipment is a significant responsibility that requires diligent attention to safety. By following the top tips for heavy equipment operation safety outlined in this article, operators can help prevent accidents, injuries, and costly downtime. Always prioritize safety, receive proper training, and promote a safety-first culture on your worksite. With these measures in place, heavy equipment operation can be both productive and safe.

Feel free to share your thoughts and continue the discussion in the comments section, don’t forget to share the article with your friends or your favorite social media. Hope it is useful!