alwepo.com, Shrinkage in Casting – Shrinkage is an inherent phenomenon in casting processes, characterized by the contraction of metal as it transforms from a liquid state to a solid one. This article delves into the causes of shrinkage in casting, the defects it can induce, and the various solutions employed to mitigate its effects.

Introduction to Shrinkage in Casting

Metal undergoes solidification shrinkage as it cools from a molten state to room temperature. Additionally, it experiences thermal contraction during the cooling process. These factors contribute to the overall shrinkage observed in cast parts. To compensate for this shrinkage, castings are designed with specific allowances to achieve the desired dimensions. However, despite these allowances, shrinkage can still lead to defects in cast products, potentially compromising their integrity and functionality.

Causes of Shrinkage Defects

Shrinkage defects in castings can be attributed to various factors, including insufficient liquid metal available during solidification, improper mold design, and inadequate cooling techniques. The following are some of the primary causes of shrinkage defects:

- Insufficient Liquid Metal: When the metal cools and shrinks with insufficient liquid available to fill any voids, surface defects such as pipes or sinks may form. These defects are open to the atmosphere, allowing air to replace the molten metal.

- Cracks and Hot Tears: Cracks and hot tears typically form during the final stages of solidification, especially around abrupt changes in the casting’s geometry or areas of high stress concentration.

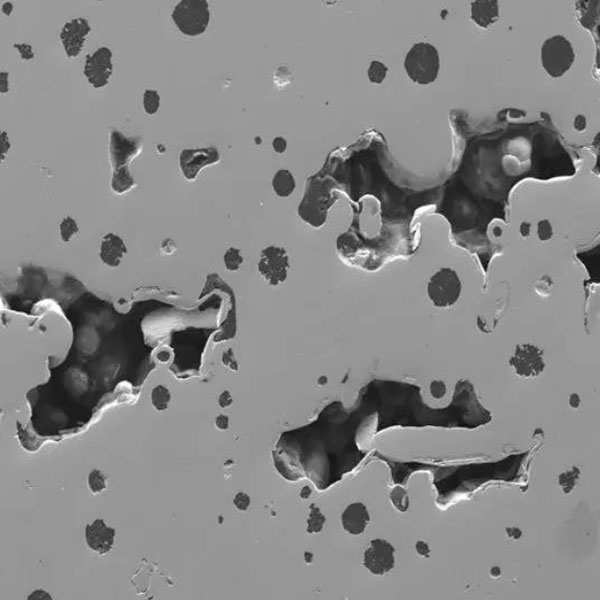

- Porosity: Porosity, caused by trapped gases or shrinkage during cooling, is one of the most common defects in castings. Shrinkage porosity appears as small holes or cracks on the surface of the casting and can compromise its structural integrity.

- Improper Mold Design: Inadequate mold design, including insufficient sprue size or improper gating systems, can lead to uneven metal flow and increased susceptibility to shrinkage defects.

Process Shrinkage in Casting

Casting, a cornerstone of metal manufacturing, allows for the creation of intricate and versatile parts. However, a hidden foe lurks within this process – process shrinkage. This phenomenon, arising from the fundamental nature of matter, can disrupt the casting process and compromise the final product.

Understanding the Shrinkage Phenomenon

Process shrinkage occurs due to the change in volume that metals undergo during solidification and cooling. As molten metal transitions from a liquid state to a solid state, its molecules pack themselves more tightly, resulting in a decrease in overall volume. This shrinkage can manifest in two primary ways:

-

Liquid Shrinkage: This occurs as the molten metal cools but remains in its liquid state. While typically less significant from a casting design perspective, it can contribute to the overall volume reduction.

-

Solidification Shrinkage: This is the major culprit for casting issues. As the metal solidifies and transforms into a solid structure, the tighter packing of molecules leads to a more pronounced volume reduction. This solidification shrinkage is what casting professionals strive to manage and minimize.

Consequences of Casting Shrinkage

Uncontrolled process shrinkage can have a number of negative consequences for cast products:

- Reduced Structural Integrity: Shrinkage defects, essentially internal voids within the casting, weaken the overall structure. This can significantly reduce the ability of the cast part to bear loads and stresses, potentially leading to failures under pressure.

- Increased Risk of Failure or Leakage: Shrinkage cavities can act as internal pathways for fluids or gases to leak through. This can compromise the functionality of the part, particularly for components designed to contain liquids or withstand pressure.

- Dimensional Inaccuracy: Shrinkage alters the final dimensions of the cast part compared to the intended design. This can lead to issues during assembly with other components or affect the functionality of the part itself.

- Degraded Surface Finish: In some cases, shrinkage defects can manifest on the surface of the casting, resulting in a rough and uneven finish. This can be aesthetically displeasing and may even impact the part’s functionality.

Combating the Shrinkage Challenge

Fortunately, casting professionals have a toolbox of strategies to mitigate the effects of process shrinkage:

- Proper Mold Design: The design of the mold plays a critical role. Techniques like incorporating strategically sized sprue wells, well-designed gating systems, and properly placed risers can help ensure a more controlled flow of molten metal and provide additional material to compensate for shrinkage as it occurs.

- Precise Control of Metal Flow: Maintaining the metal within an appropriate temperature range during pouring optimizes its flow characteristics. Additionally, managing mold temperature ensures a balanced solidification rate, minimizing the formation of shrinkage defects.

- Simulation Software: Advanced software allows designers to virtually simulate the casting process, identifying potential shrinkage hotspots before the mold is even manufactured. This proactive approach allows for adjustments to mold design and gating systems to minimize shrinkage risks.

Effects of Shrinkage Defects

While casting offers a versatile and efficient method for producing metal parts, the process is not without its challenges. Shrinkage defects, those unwelcome cavities and cracks that form as molten metal cools and solidifies, can significantly compromise the quality and functionality of cast products. Let’s delve deeper into the detrimental effects of shrinkage defects and understand why they pose such a threat.

1. Reduced Structural Integrity

The primary concern associated with shrinkage defects is their detrimental impact on the structural integrity of the cast part. Castings are designed to withstand specific loads and stresses. Shrinkage defects, acting essentially as internal voids or weak points, can significantly reduce the ability of the casting to bear these loads. Imagine a bridge beam with a large internal cavity – its ability to support weight would be severely compromised. Similarly, shrinkage defects in a critical engine component could lead to catastrophic failure under pressure.

2. Increased Risk of Failure or Leakage

Shrinkage defects not only weaken the structure but can also create pathways for leaks or fluid flow within the casting. These defects can act as internal channels, compromising the ability of the casting to contain fluids or gases. For instance, a leaking pipe due to shrinkage defects in its wall could lead to environmental damage or equipment malfunction. In pressure vessels, such defects could pose a serious safety hazard.

3. Compromised Dimensional Accuracy

Shrinkage creates a dimensional change in the solidifying metal. The presence of shrinkage defects can alter the final dimensions of the cast part, deviating from the intended design specifications. This deviation can affect the functionality of the part or create challenges during assembly with other components. For example, a bearing with a slightly smaller inner diameter due to shrinkage defects might not fit its mating shaft properly, leading to operational issues.

4. Degradation of Surface Finish

In some cases, shrinkage defects can manifest on the surface of the cast part. This can lead to a rough, uneven surface finish, which may not be aesthetically pleasing or may even impact the functionality of the part. For instance, a casting with a rough surface finish may be more prone to corrosion or may not provide a smooth and secure interface for other components.

The Domino Effect of Shrinkage Defects

It’s important to remember that the effects of shrinkage defects can often have a ripple effect. A compromised structural component can lead to equipment failure, while a leaking pipe can trigger environmental damage or production downtime. Similarly, even minor dimensional discrepancies can snowball into assembly issues and production delays.

Solutions to Mitigate Shrinkage Defects

Addressing shrinkage defects requires a combination of proper design, process optimization, and quality control measures. The following are some common solutions employed to mitigate shrinkage defects in casting:

1. Proper Mold Design

Designing molds with appropriate sprue size, gating systems, and risers is essential to ensure uniform metal flow and minimize shrinkage defects. A properly sized sprue attached directly to heavy sections of the mold can provide the feed material necessary to counteract shrinkage.

2. Uniform Metal Flow

Ensuring uniform metal flow into the cavity is critical to preventing shrinkage defects. Using a larger central sprue or multiple sprue arrangements can help achieve an even supply of material and reduce the risk of defects.

3. Temperature Control

Maintaining proper metal and mold temperatures during casting is essential to minimizing shrinkage defects. Metal should be heated to the appropriate temperature range before pouring, and mold temperatures should be controlled to promote uniform solidification.

4. Simulation Software

Utilizing simulation software can help optimize the filling of cavities and predict the occurrence of shrinkage defects. By simulating the casting process, designers can identify potential issues and implement corrective measures before production.

5. Post-Cast Repairs

Vacuum impregnation is a post-casting repair process used to fix porosity problems in castings. Sealants are introduced into the casting under pressure or vacuum to eliminate any leaks caused by porosity, ensuring the integrity of the finished product.

Conclusion

Shrinkage in casting is a common phenomenon that can lead to various defects and quality issues in cast products. By understanding the causes of shrinkage defects and implementing appropriate solutions, manufacturers can optimize their casting processes and produce high-quality, defect-free components. With proper design, process control, and quality assurance measures, shrinkage defects can be effectively mitigated, ensuring the reliability and performance of cast products.

Leave a Reply

View Comments