alwepo.com, Over the past decade, a major shift has unfolded across the global supply chain landscape: the rapid rise of reshoring. Once heavily dependent on overseas production—particularly in China, Southeast Asia, and Latin America—American companies are now bringing manufacturing operations back to the United States at an unprecedented rate. This movement has reshaped corporate strategies, political narratives, and the long-term vision of U.S. competitiveness in the global marketplace.

But why is this happening now? The answer is a combination of economic pressures, geopolitical instability, supply chain fragility, rising global labor costs, and transformative technologies that make U.S.-based manufacturing more feasible and cost-effective than ever before. Reshoring is not merely a trend; it is becoming a strategic imperative for industries seeking stability, agility, and operational excellence.

This article explores why American companies are reshoring, the forces behind the movement, and what this means for the future of U.S. manufacturing, workers, and innovation.

What Is Reshoring?

Reshoring refers to the process of returning manufacturing and production operations back to the company’s home country—in this case, the United States. It is often contrasted with:

- Offshoring: Moving production to low-cost foreign countries.

- Nearshoring: Shifting operations to nearby countries, such as Mexico or Canada.

- Friendshoring: Relocating supply chains to politically aligned nations.

Reshoring is driven by a strategic pursuit of control, resilience, and reliability. It is especially prominent in industries such as:

- Automotive

- Electronics

- Pharmaceuticals

- Aerospace

- Defense

- Medical devices

- Renewable energy

- Semiconductors

As global economic uncertainties continue to rise, reshoring has emerged as a cornerstone of the United States’ industrial renewal.

Why American Companies Are Reshoring: Key Drivers Behind the Movement

1. Supply Chain Disruptions Exposed by the Pandemic

The COVID-19 pandemic revealed critical weaknesses in long, complex, and globally dispersed supply chains. Companies faced:

- Severe material shortages

- Unpredictable shipping schedules

- Port congestion

- Surging freight costs

- Shutdowns in critical supplier countries

Businesses realized that relying heavily on distant suppliers created unacceptable risks.

SEO Keyword Focus: supply chain resilience, reshoring, U.S. manufacturing

By bringing manufacturing closer to home, companies gain:

- More reliable production

- Faster response times

- Reduced dependence on foreign governments

- Greater control over inventory

Reshoring ultimately strengthens supply chain resilience and mitigates future disruptions.

2. Rising Labor Costs in Traditional Offshoring Countries

For decades, low-cost labor in Asia—especially China—was the primary reason companies chose to offshore production. But labor costs have been rising sharply:

- Chinese manufacturing wages have increased more than 400% in 20 years

- Southeast Asia, though cheaper, is also trending upward

- Labor shortages are affecting factories across the region

As the cost gap narrows, the financial advantage of offshoring diminishes. When transportation, risks, compliance, and delays are considered, many companies find that reshoring now makes better long-term economic sense.

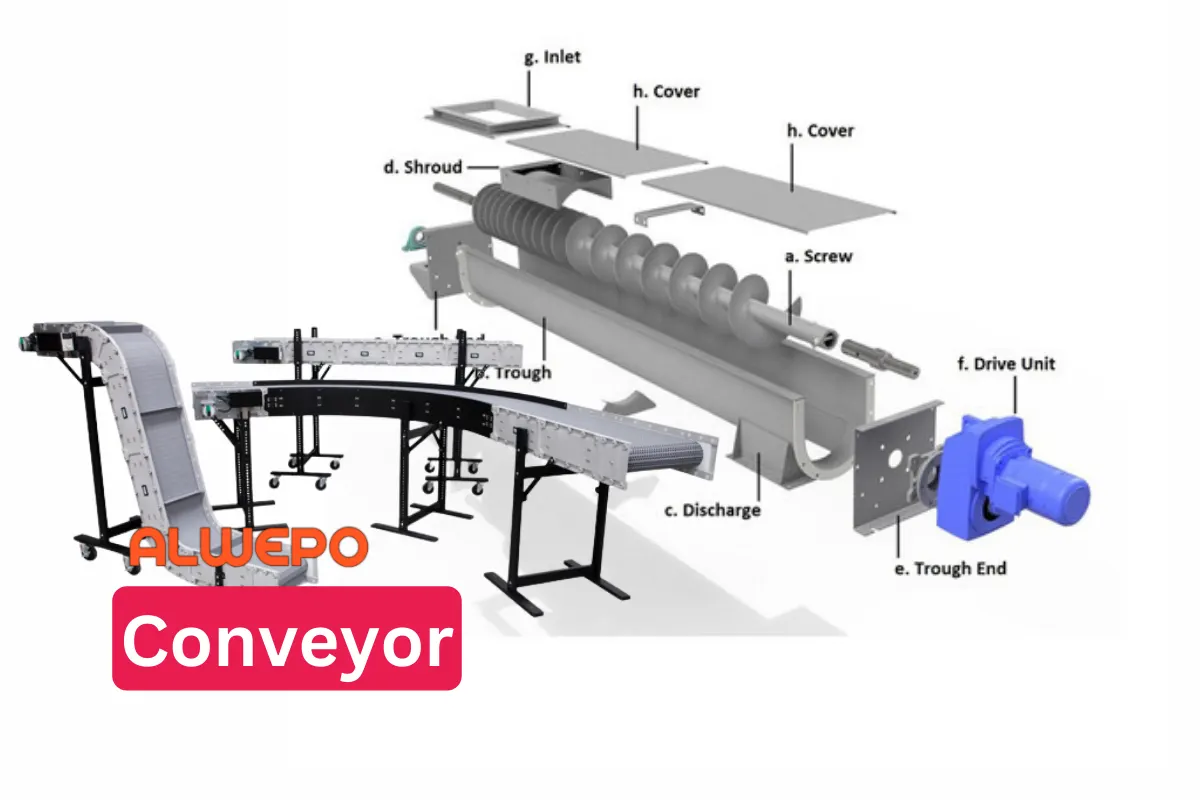

3. Automation and Industry 4.0 Make U.S. Production Competitive Again

One of the most influential reshoring drivers is the rapid adoption of advanced manufacturing technologies, including:

- Robotics

- Artificial intelligence (AI)

- Digital twins

- Industrial IoT

- Smart factories

- Machine vision

- 3D printing

These technologies dramatically reduce labor requirements and boost efficiency, making high-wage countries like the U.S. competitive again.

How automation enables reshoring:

- Robotics handle repetitive tasks faster and more accurately

- Sensors and AI optimize equipment performance

- Digital twins reduce downtime and errors

- Predictive analytics prevent failures and improve quality

- Automation reduces per-unit labor costs

Instead of competing on labor, companies now compete on technology—and the U.S. leads in innovation.

4. Geopolitical Tensions and National Security Concerns

Rising tensions between the U.S. and China have pushed companies to re-evaluate their dependence on risky foreign supply chains. Industries considered vital for national security—such as microchips, aerospace, defense technology, and pharmaceuticals—are now under pressure to operate domestically.

Policies such as:

- The CHIPS and Science Act

- The Inflation Reduction Act (IRA)

- Buy American provisions

- Federal incentives for domestic manufacturing

…are designed to reduce reliance on foreign suppliers and encourage strategic reshoring.

5. Improved Quality Control and Faster Innovation Cycles

Manufacturing products far from corporate headquarters makes quality control and design iteration difficult. Problems often arise when communication barriers, long lead times, and factory oversight challenges slow down innovation.

By reshoring, companies gain:

- Immediate access to their production teams

- Faster prototyping and testing

- Greater accountability

- Enhanced product quality

- Shorter design–to–market cycles

For industries like electronics, where speed is everything, being geographically close to production is a major competitive advantage.

6. Customer Demand for “Made in USA” Products

The “Made in USA” label has regained its appeal, especially in sectors like:

- Apparel

- Electronics

- Household goods

- Tools

- Automotive

Consumers increasingly associate American-made products with:

- Higher quality

- Ethical labor practices

- Environmental responsibility

- Patriotism and national pride

Companies respond to this demand not only to boost sales, but also to build stronger brand loyalty.

7. ESG, Sustainability, and Environmental Responsibility

Many global companies have made commitments to reduce their carbon footprint. Offshoring often contradicts sustainability goals due to:

- Long-distance shipping emissions

- Weak environmental regulations in manufacturing countries

- Energy-intensive logistics

Reshoring reduces environmental impact significantly. In the U.S., companies benefit from:

- Cleaner energy sources

- Stricter regulations

- Improved waste management

- Sustainable supply chain integration

ESG (Environmental, Social, Governance) considerations now play a major role in boardroom decisions.

Industries Leading the Reshoring Revolution

1. Semiconductors

The chip shortage revealed vulnerabilities in the tech supply chain. The U.S. now invests heavily in building domestic semiconductor fabs.

Major companies expanding in the U.S.:

- Intel

- TSMC

- Samsung

- Micron

These projects are worth hundreds of billions of dollars.

2. Automotive and EV Manufacturing

Electric vehicles require complex components like:

- Batteries

- Motors

- Power electronics

To reduce dependency on Asia, automakers are building battery and EV plants in:

- Michigan

- Tennessee

- Ohio

- Texas

- Georgia

Companies include Ford, GM, Tesla, and emerging EV brands.

3. Pharmaceuticals and Medical Devices

Shortages of essential drugs and protective equipment during COVID-19 exposed critical vulnerabilities. The U.S. is reshoring production of:

- Antibiotics

- IV fluids

- PPE

- Generic drugs

- Medical equipment

This is a national security priority.

4. Aerospace and Defense

The U.S. government strongly encourages domestic production of:

- Aircraft components

- Satellites

- Drones

- Military equipment

Reshoring ensures security and supply chain integrity.

5. Consumer Goods and Apparel

Even traditionally low-margin industries are reshoring due to rising overseas costs and consumer demand for sustainable products.

Benefits of Reshoring for American Companies

1. Greater Supply Chain Control

Reshoring eliminates uncertainty caused by:

- Geopolitical conflicts

- Sudden lockdowns

- Long-distance transportation

- Import restrictions

Control leads to improved operational stability.

2. Shorter Lead Times and Faster Delivery

Customers expect rapid shipping. Domestic manufacturing enables:

- Faster production cycles

- Same-week or same-day shipping

- Reduced stockouts

This is especially valuable for e-commerce companies.

3. Protection of Intellectual Property

IP theft is a serious concern in offshore regions. Reshoring protects:

- Proprietary technologies

- Patents

- Formulas

- Trade secrets

Security is non-negotiable in high-tech sectors.

4. Enhanced Product Quality

Proximity enables tight quality control, faster response to defects, and improved product reliability.

5. Boosting the U.S. Workforce

Reshoring supports the creation of:

- Skilled manufacturing jobs

- Engineering roles

- Automation and robotics jobs

- Supply chain positions

This strengthens local economies and revitalizes industrial communities.

Challenges and Barriers to Reshoring

Although reshoring offers major advantages, companies still face several challenges:

1. Shortage of Skilled Labor

Many American workers lack training in modern manufacturing technologies. Companies need to invest in:

- Workforce development

- Apprenticeship programs

- Technical education partnerships

2. Higher Operating Costs

U.S. expenses—labor, energy, taxes, compliance—can be higher than offshore locations. Automation helps, but costs remain a concern.

3. Infrastructure and Logistics Limitations

Some regions lack adequate:

- Rail connections

- Ports

- Clean energy access

- Industrial zones

Infrastructure investment is essential.

4. Transition Costs

Moving production from overseas involves:

- Factory closures

- Supplier changes

- New equipment installation

- Workforce training

- Compliance adjustments

These transitions require significant capital and time.

Strategies for Successful Reshoring

Companies that successfully reshore adopt strong strategies, including:

1. Investing in Automation and Smart Factories

Robotics, sensors, and AI reduce operating costs and boost efficiency.

2. Building Local Supplier Networks

A strong domestic supply base reduces risks and supports speed.

3. Leveraging Federal and State Incentives

Governments offer:

- Tax credits

- Grants

- Low-interest loans

- Workforce training support

4. Adopting Agile Manufacturing Models

Modular production and flexible lines allow companies to scale efficiently.

5. Upskilling the Workforce

Training workers in:

- Robotics

- AI

- CNC machining

- Quality management

…helps ensure productivity and operational excellence.

The Future of Reshoring: What Comes Next?

Reshoring is not a short-term trend. It is part of a long-term effort to redefine American industrial strategy. The future will be shaped by:

- Increasing automation

- Expansion of domestic chip manufacturing

- Growth of renewable energy production

- More sustainable supply chains

- Rising consumer demand for domestic products

- Ongoing geopolitical instability

In the coming years, the U.S. is expected to become a global leader in advanced, technology-driven manufacturing.

Conclusion: The New Era of American Manufacturing

Reshoring represents a major turning point in U.S. economic strategy. American companies are no longer chasing the lowest labor cost—they are seeking resilience, quality, speed, innovation, and control. By bringing manufacturing back home, businesses strengthen supply chains, improve customer satisfaction, protect intellectual property, and drive national economic growth.

As global pressures continue to rise, reshoring will only accelerate. The United States is entering a new era of industrial revitalization—powered by technology, innovation, and a renewed commitment to manufacturing excellence.

.jpg)