alwepo, Dragline Excavators – In the world of heavy construction and mining, large-scale excavation tasks often require robust machinery to get the job done efficiently. One such impressive piece of equipment is the Dragline Excavator. In this article, we will delve into the world of Dragline Excavators, exploring their history, components, working mechanisms, applications, advantages, limitations, maintenance, and safety considerations.

What is a Dragline Excavator?

A Dragline Excavator is a colossal piece of construction equipment designed for heavy-duty excavation projects. It consists of a long boom with a bucket suspended from it. The bucket is connected via ropes and pulleys, allowing it to be raised and lowered to perform digging and loading operations effectively.

History of Dragline Excavators

The concept of the Dragline Excavator dates back to the late 19th century when it was first developed for use in the civil engineering and construction industries. Over the years, advancements in engineering and technology have led to the development of even larger and more powerful Dragline Excavators, capable of handling mammoth tasks in the mining sector.

Components of a Dragline Excavator

A Dragline Excavator comprises several key components that work in harmony to achieve remarkable excavation capabilities. These components include:

1. Boom

The boom is the long, inclined structure that supports the bucket and allows it to move over the excavation site. It provides the necessary reach and height for efficient digging.

2. Bucket

The bucket is a large, open container suspended at the end of the boom. It is responsible for digging and scooping up materials, such as soil, rocks, and minerals.

3. House

The house, also known as the cab, is the operator’s compartment situated on top of the machine. It houses the controls and offers a panoramic view of the worksite, ensuring precise operation.

4. Counterweight

The counterweight is a heavy mass attached at the rear of the dragline excavator. It serves to counterbalance the weight of the boom and bucket, providing stability during operation.

5. Undercarriage

The undercarriage is the lower part of the machine that rests on tracks or wheels. It facilitates the movement of the dragline excavator across the worksite.

6. Power System

The power system includes the engine and associated components responsible for powering the dragline excavator’s movements and operations.

Types of Dragline Excavator

Dragline excavators are formidable machines used in heavy construction and mining industries for massive excavation tasks. These powerful giants come in various types, each designed to cater to specific needs and requirements. In this article, we will explore the different types of dragline excavators and their unique characteristics.

1. Walking Dragline Excavators

Walking dragline excavators, also known as mobile draglines, are the most common type of dragline excavators. They are equipped with tracks or wheels that allow them to move independently across the worksite. These machines are highly versatile and well-suited for open-pit mining and large-scale earthmoving projects. Walking draglines are known for their efficiency, mobility, and ability to handle a wide range of materials.

2. Crawler Dragline Excavators

Crawler dragline excavators are similar to walking draglines in terms of mobility, but they are typically larger and more powerful. These machines are mounted on crawler tracks, providing exceptional stability and weight distribution. Crawler draglines are often used in deep mining operations and projects where heavy digging and lifting capacities are required. Their robust design allows them to handle tough terrains and adverse conditions.

3. Backhoe Dragline Excavators

Backhoe dragline excavators, as the name suggests, combine the functionalities of a dragline and a backhoe. These machines have a bucket at the front, similar to a backhoe, and a long boom with a bucket suspended from it, like a dragline. Backhoe draglines are known for their versatility, as they can perform both dragging and digging operations efficiently. They are commonly used in construction projects that require a wide range of excavation tasks.

4. Front Shovel Dragline Excavators

Front shovel dragline excavators are specialized machines designed for specific excavation purposes. Instead of a traditional bucket, these excavators have a shovel attachment at the end of the boom. The shovel is used for digging and loading materials, making front shovel draglines ideal for mining operations that involve handling loose materials, such as sand and gravel.

5. Electric Dragline Excavators

Electric dragline excavators are environmentally-friendly alternatives to their diesel-powered counterparts. These machines are powered by electricity, which reduces emissions and lowers operating costs. Electric draglines are known for their energy efficiency and are often preferred in projects where sustainability and reduced carbon footprint are crucial considerations.

6. Diesel Dragline Excavators

Diesel dragline excavators are traditional models powered by diesel engines. While they may produce more emissions compared to electric versions, they offer higher mobility and are suitable for projects in remote areas without access to electricity. Diesel draglines are favored for their reliability and robustness in handling demanding tasks.

7. Dragline Buckets

Aside from the different types of dragline excavators, various bucket configurations are available to enhance their capabilities. Dragline buckets come in various sizes and shapes, such as:

- Clamshell Bucket: Suitable for grabbing and handling loose materials.

- Drag Bucket: Designed for efficient dragging and scooping of materials from the ground.

- Clamshell Dragline Bucket: Combines the functionalities of both the clamshell and drag bucket for versatile operations.

- Rock Bucket: Specifically designed for digging and handling rocky terrains.

How Dragline Excavators Work

Understanding the working mechanisms of a Dragline Excavator is essential to comprehend its efficiency in large-scale excavation projects. The primary working mechanisms include:

1. Walking Mechanism

The walking mechanism enables the dragline excavator to move across the worksite. Depending on the model, some machines are equipped with tracks, while others have wheels.

2. Dragging Mechanism

The dragging mechanism allows the bucket to be dragged towards the machine for excavation purposes. This process is crucial for digging into the earth and capturing materials.

3. Dumping Mechanism

The dumping mechanism involves raising the loaded bucket and positioning it over a designated area to release its contents. This is essential for transporting materials to trucks or other storage areas.

Applications of Dragline Excavators

Dragline excavators are heavy-duty machines with immense capabilities, making them indispensable assets in various industries. Their impressive digging and lifting capacities allow for efficient handling of vast quantities of materials. Let’s explore the diverse applications of dragline excavators across different sectors:

1. Large-Scale Mining Operations

One of the primary applications of dragline excavators is in large-scale mining operations. These machines are commonly used for extracting coal, iron ore, and other valuable minerals from open-pit mines. Their ability to remove significant quantities of overburden (soil, rock, and other materials covering the mineral deposit) efficiently makes them ideal for maximizing productivity in mining activities.

2. Open-Pit Mining

Dragline excavators are particularly well-suited for open-pit mining, where minerals or ores are extracted from the surface. In open-pit mining, the terrain is relatively flat, allowing the dragline to move freely and efficiently across the site. The dragline’s massive bucket can remove large amounts of material, helping to expose the valuable mineral deposits below the surface.

3. Dredging Projects

Dredging is the process of excavating and removing sediment and debris from bodies of water, such as rivers, lakes, and harbors. Dragline excavators equipped with specialized dredging buckets are employed in dredging projects to deepen waterways, maintain navigation channels, and reclaim land from underwater areas.

4. Civil Engineering Projects with Extensive Earthmoving Requirements

In civil engineering projects that involve significant earthmoving tasks, dragline excavators play a vital role. These projects may include the construction of highways, railways, canals, and reservoirs. The dragline’s ability to remove large volumes of soil and rock efficiently helps in creating the required foundation and space for these infrastructures.

5. Removing Overburden and Stripping Operations

In various earthmoving projects, the dragline excavator is utilized to remove overburden or strip away the top layer of soil and rock to access underlying mineral deposits or prepare the site for construction. This process is common in mining, quarrying, and construction projects.

6. Land Reclamation

Land reclamation involves transforming barren or waterlogged areas into usable land for agriculture, industrial, or residential purposes. Dragline excavators are used to remove unwanted materials and reshape the landscape, creating valuable land for development.

7. Precious Metal and Gemstone Mining

In precious metal and gemstone mining, where precision is crucial, dragline excavators are employed for selective mining. These machines can carefully extract valuable minerals without damaging or contaminating the precious resources.

8. Environmental Restoration

Dragline excavators are also employed in environmental restoration projects to clean up contaminated sites or restore ecosystems. They can efficiently remove hazardous materials and restore the land to its original state.

9. Debris Cleanup after Natural Disasters

After natural disasters such as hurricanes, floods, or earthquakes, dragline excavators are deployed for debris cleanup and restoration efforts. Their large buckets can clear debris and rubble quickly, aiding in the recovery process.

10. Building and Expanding Reservoirs

In water resource projects, dragline excavators are used to build and expand reservoirs. They can efficiently excavate soil and rock to create storage space for water, which is vital for irrigation, hydroelectric power generation, and water supply.

Advantages of Dragline Excavators

The use of Dragline Excavators offers several advantages:

- High efficiency in handling vast quantities of materials

- Reduced labor requirements due to automated operations

- Cost-effectiveness for significant excavation tasks

Limitations of Dragline Excavators

While highly efficient, Dragline Excavators also have some limitations:

- Limited mobility compared to other types of excavators

- High initial investment costs

- Maintenance challenges due to the machine’s size and complexity

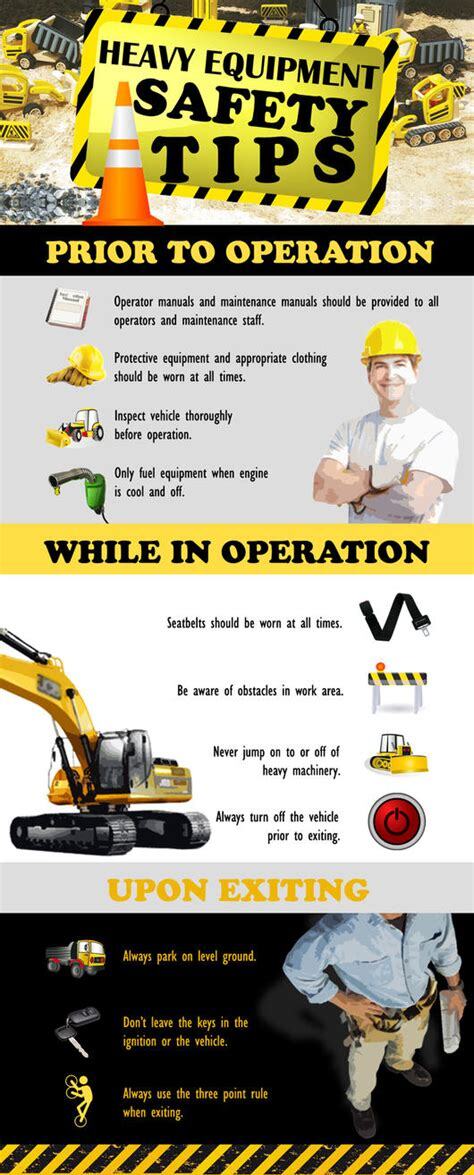

Maintenance and Safety Considerations

Regular maintenance is crucial to ensure the longevity and optimal performance of a Dragline Excavator. Proper safety protocols should be followed to prevent accidents and ensure the well-being of operators and personnel.

Future of Dragline Excavators

The future of Dragline Excavators looks promising as technology continues to advance. Innovations may focus on improving mobility, efficiency, and safety features, making them even more versatile and reliable for various industries.

Conclusion

Dragline Excavators play a vital role in modern construction and mining projects, offering unmatched capabilities in handling large-scale excavation tasks. With their powerful components, working mechanisms, and widespread applications, they continue to be indispensable assets in the heavy equipment industry.

Leave a Reply

View Comments