Hello alwepo friends, in this article we will discuss The Future of Heavy Equipment Industry: What You Need to Know. The heavy equipment industry plays a crucial role in various sectors, including construction, mining, agriculture, and transportation. As technology continues to advance at a rapid pace, it is important to understand the future trends and developments in this industry. In this comprehensive guide, we will explore the emerging technologies, market trends, environmental considerations, and challenges that will shape the future of the heavy equipment industry. So, let’s dive in!

Introduction: The Future of Heavy Equipment Industry

The heavy equipment industry has come a long way since its inception. From simple mechanical machines to sophisticated and technologically advanced equipment, this industry has continuously evolved to meet the growing demands of various sectors. As we move further into the 21st century, the future of the heavy equipment industry looks promising yet challenging. Rapid advancements in technology, increasing environmental concerns, and changing customer expectations are reshaping the landscape of this industry.

In this era of digital transformation, it is crucial for businesses in the heavy equipment industry to adapt to emerging trends and technologies to stay competitive. The industry is witnessing a shift towards automation, electrification, and sustainability, driven by factors such as cost-effectiveness, environmental regulations, and customer demand for more efficient and eco-friendly equipment. To thrive in this evolving landscape, industry players need to embrace innovation, collaborate with technology providers, and invest in research and development. Before continue, you can Read Also: The Pros and Cons of Buying vs. Renting Heavy Equipment.

Impact of Emerging Technologies on Heavy Equipment Industry

The heavy equipment industry is at the forefront of technological advancements. Emerging technologies are revolutionizing the way heavy equipment is designed, manufactured, operated, and maintained. Let’s explore some of the key technologies that are reshaping the industry:

Artificial Intelligence (AI) in Heavy Equipment

Artificial Intelligence (AI) is playing a transformative role in the heavy equipment industry. AI-powered systems can analyze vast amounts of data collected from equipment sensors, enabling predictive maintenance, optimizing fuel consumption, and enhancing overall operational efficiency. AI algorithms can also improve equipment safety by detecting potential hazards and alerting operators in real-time. With AI, heavy equipment can become smarter, more reliable, and better equipped to handle complex tasks.

Internet of Things (IoT) and Heavy Equipment

The Internet of Things (IoT) has opened up new possibilities for the heavy equipment industry. By connecting equipment, sensors, and other devices to the internet, IoT enables real-time monitoring, remote diagnostics, and predictive maintenance. IoT-powered solutions help equipment operators and fleet managers optimize performance, reduce downtime, and make data-driven decisions. With the ability to collect and analyze data from multiple sources, IoT is transforming the way heavy equipment is managed and operated.

Automation and Robotics in Heavy Equipment

Automation and robotics are revolutionizing the heavy equipment industry by replacing manual labor with advanced machinery. Automated equipment can perform repetitive tasks with precision, consistency, and higher productivity. Robotics technology, such as drones and autonomous vehicles, is being used for tasks like surveying, mapping, and material handling. The integration of automation and robotics improves operational efficiency, reduces labor costs, and enhances safety in challenging work environments.

Virtual Reality (VR) and Augmented Reality (AR) in Heavy Equipment

Virtual Reality (VR) and Augmented Reality (AR) technologies are transforming heavy equipment design, training, and maintenance. VR allows equipment manufacturers to create immersive experiences for design visualization, simulation, and testing. AR provides real-time information overlays, enhancing equipment operators’ situational awareness and enabling them to perform tasks more efficiently. These immersive technologies improve collaboration, training effectiveness, and equipment performance.

The Rise of Electric and Hybrid Heavy Equipment

The future of heavy equipment is increasingly electrified. Electric and hybrid heavy equipment is gaining traction due to its numerous benefits, including reduced emissions, lower operating costs, and quieter operation. Let’s take a closer look at the rise of electric and hybrid heavy equipment:

Advantages and Challenges of Electric Heavy Equipment

Electric heavy equipment offers several advantages over traditional diesel-powered machines. Electric equipment produces zero tailpipe emissions, leading to improved air quality and reduced environmental impact. Electric machines also operate more quietly, reducing noise pollution in urban areas. Additionally, electric equipment tends to have lower operating costs due to fewer maintenance requirements and lower fuel expenses. However, challenges such as limited battery range, longer charging times, and initial higher costs of electric equipment need to be addressed for wider adoption.

Hybrid Heavy Equipment: Combining Power and Efficiency

Hybrid heavy equipment combines the benefits of electric and traditional power sources. These machines use a combination of electric motors and internal combustion engines, allowing for increased fuel efficiency and reduced emissions. Hybrid systems can recover energy during braking or deceleration, which is then used to power the equipment during operation. By optimizing power usage, hybrid heavy equipment offers improved performance, reduced fuel consumption, and lower environmental impact.

Battery Technology and Charging Infrastructure

The success of electric heavy equipment relies on advancements in battery technology and the availability of a robust charging infrastructure. Battery technology continues to evolve, offering higher energy densities, faster charging capabilities, and longer lifespans. With improved batteries, electric heavy equipment can achieve longer operating times and faster charging cycles, making them more practical for various applications. Moreover, the establishment of a widespread charging infrastructure is essential to support the adoption of electric heavy equipment on a larger scale.

Sustainable Practices in the Heavy Equipment Industry

As environmental concerns grow, the heavy equipment industry is embracing sustainable practices to minimize its impact on the environment. Here are some key aspects of sustainability in the industry:

Environmental Impact of Heavy Equipment

Heavy equipment operations can have significant environmental consequences, including air and noise pollution, habitat destruction, and soil erosion. To address these issues, industry players are adopting cleaner technologies, such as low-emission engines and exhaust after-treatment systems, to reduce the environmental footprint of heavy equipment. Additionally, equipment manufacturers are focusing on recyclability and sustainable materials in equipment design to minimize waste and promote circular economy principles.

Emission Regulations and Compliance

Stringent emission regulations are driving the heavy equipment industry towards cleaner and more fuel-efficient solutions. Governments worldwide are implementing emission standards and regulations that require equipment manufacturers to reduce harmful emissions from their machines. Compliance with these regulations is essential for manufacturers to remain competitive and meet the demands of environmentally conscious customers. As a result, the industry is investing in research and development to develop innovative emission control technologies.

Innovations in Fuel Efficiency

Fuel efficiency is a crucial aspect of sustainability in the heavy equipment industry. Improving the fuel efficiency of equipment can significantly reduce carbon emissions and operating costs. To achieve this, manufacturers are employing advanced engine technologies, optimizing equipment designs for reduced drag and improved aerodynamics, and integrating hybrid power systems. By embracing fuel-efficient solutions, the industry can contribute to energy conservation and environmental preservation.

Renewable Energy Sources for Heavy Equipment

Renewable energy sources, such as solar and wind power, are being explored for powering heavy equipment. Solar panels installed on equipment can harness the sun’s energy to power auxiliary systems, reducing the need for engine-generated electricity. Wind turbines integrated into equipment designs can capture wind energy and convert it into electrical power. The utilization of renewable energy sources in heavy equipment reduces dependence on fossil fuels and promotes sustainable practices.

Future Trends in Heavy Equipment Manufacturing

The heavy equipment manufacturing sector is undergoing significant transformations driven by technological advancements and changing market dynamics. Let’s explore some of the future trends shaping the industry:

Advanced Materials and Lightweight Design

The use of advanced materials, such as high-strength alloys, composites, and lightweight metals, is becoming increasingly prevalent in heavy equipment manufacturing. These materials offer higher strength-to-weight ratios, improved durability, and reduced fuel consumption. By adopting lightweight design principles, equipment manufacturers can enhance performance, payload capacity, and overall efficiency while minimizing environmental impact.

3D Printing in Heavy Equipment Manufacturing

3D printing, also known as additive manufacturing, is revolutionizing the heavy equipment manufacturing process. It enables the creation of complex geometries, customization, and rapid prototyping, leading to reduced production times and costs. With 3D printing, manufacturers can optimize designs, create lightweight components, and streamline supply chains. The technology has the potential to revolutionize spare parts management and equipment maintenance by allowing on-demand printing of specific components.

Modular and Customizable Equipment

The future of heavy equipment lies in modular and customizable designs. Modular equipment allows for interchangeable components, enabling easier customization for specific applications. This flexibility ensures that equipment can adapt to changing requirements and reduces the need for purchasing entirely new machines. Moreover, modular designs simplify maintenance and repairs by replacing only the necessary modules, improving uptime and reducing costs.

Data Analytics and Predictive Maintenance

The increasing availability of data from sensors and equipment systems is enabling the implementation of data analytics and predictive maintenance strategies. By analyzing equipment performance data, manufacturers can identify potential issues before they occur, allowing for proactive maintenance and reducing costly downtime. Predictive maintenance improves equipment reliability, optimizes maintenance schedules, and increases overall productivity. Furthermore, data analytics can provide valuable insights into equipment usage patterns, operator behavior, and opportunities for efficiency improvements.

The Role of Autonomous Heavy Equipment

Autonomous heavy equipment is revolutionizing the industry by eliminating the need for human operators in certain tasks. Here are some key aspects of autonomous heavy equipment:

Benefits and Challenges of Autonomous Equipment

Autonomous heavy equipment offers several benefits, including improved safety, increased productivity, and reduced labor costs. With autonomous machines, the risk of human error and accidents can be minimized, enhancing overall job site safety. Additionally, autonomous equipment can operate around the clock without fatigue, resulting in increased productivity and reduced project timelines. However, challenges such as regulatory frameworks, technological reliability, and public acceptance need to be addressed before widespread adoption of autonomous equipment.

Automation in Mining and Construction

The mining and construction sectors are prime candidates for automation due to their repetitive and hazardous nature. Autonomous vehicles, drones, and robotic systems are being used for tasks like excavation, material handling, and surveying. These technologies enable precise and efficient operations, leading to improved safety, higher productivity, and reduced operational costs. Automation also allows for better data collection and analysis, leading to more informed decision-making and optimized workflows.

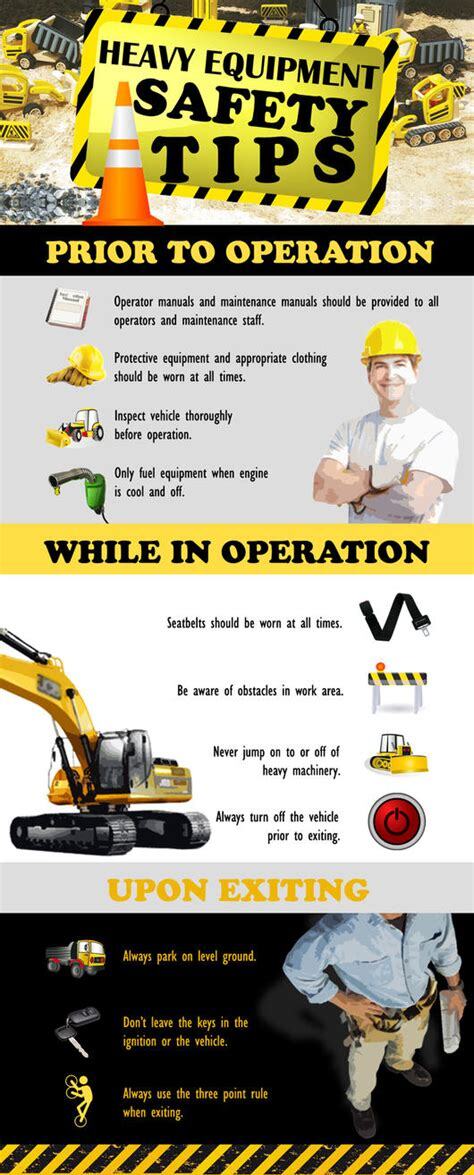

Safety Considerations and Regulations

As autonomous heavy equipment becomes more prevalent, safety considerations and regulations become paramount. It is crucial to establish industry-wide safety standards and protocols for autonomous equipment. This includes robust cybersecurity measures to protect against potential hacking threats. Additionally, regulations need to address liability concerns and define the roles and responsibilities of stakeholders involved in autonomous operations. By ensuring safety and regulatory compliance, the industry can fully leverage the potential of autonomous heavy equipment.

Adapting to Changing Customer Demands

The heavy equipment industry must continuously adapt to meet changing customer demands. Here are some key factors influencing customer preferences:

Sustainability and Environmental Considerations

Customers are increasingly prioritizing sustainability and environmental impact when choosing heavy equipment. They seek machines with lower emissions, improved fuel efficiency, and sustainable manufacturing practices. Equipment manufacturers need to align their offerings with these customer preferences by developing eco-friendly solutions and incorporating sustainable materials and technologies into their products.

Connectivity and Data-Driven Insights

Connectivity and data-driven insights are becoming essential for customers in the heavy equipment industry. They expect equipment to be equipped with telematics systems that provide real-time data on machine performance, fuel consumption, and maintenance requirements. Manufacturers that offer comprehensive connectivity solutions and data analytics capabilities can provide customers with valuable insights for optimizing equipment usage, reducing costs, and improving overall efficiency.

Equipment Versatility and Adaptability

Customers are looking for heavy equipment that offers versatility and adaptability for various applications. Machines that can easily switch between different attachments and perform multiple tasks are highly sought after. Equipment manufacturers need to design modular and adaptable equipment that can meet the diverse needs of customers across different industries.

User-Friendly Interfaces and Operator Comfort

Equipment usability and operator comfort are significant considerations for customers. User-friendly interfaces, ergonomic designs, and enhanced operator comfort contribute to increased productivity, reduced fatigue, and improved job satisfaction. Manufacturers need to focus on human-centered design principles to create equipment that is intuitive to operate and provides a comfortable working environment for operators.

The Future of Heavy Equipment Industry: What You Need to Know

As we have explored throughout this article, the future of the heavy equipment industry is filled with exciting possibilities and transformative technologies. From the integration of AI and IoT to the rise of electric and hybrid equipment, the industry is undergoing a significant evolution. Sustainable practices, advanced materials, and autonomous equipment are reshaping manufacturing processes and customer expectations.

To thrive in this changing landscape, industry players must embrace innovation, prioritize sustainability, and adapt to the evolving needs of their customers. By leveraging emerging technologies, improving fuel efficiency, and ensuring safety and regulatory compliance, the heavy equipment industry can pave the way for a more sustainable and efficient future.

Conclusion

The future of the heavy equipment industry holds immense potential for growth, driven by technological advancements and changing market dynamics. With a focus on sustainability, customer demands, and disruptive innovations, the industry is poised for remarkable transformations. As the industry continues to evolve, it is crucial for stakeholders to stay informed, embrace new technologies, and collaborate to shape a future that is efficient, environmentally friendly, and economically sustainable.

Thus the article about The Future of Heavy Equipment Industry: What You Need to Know. Feel free to share your thoughts and continue the discussion in the comments section, don’t forget to share the article with your friends or your favorite social media. Hope it is useful!

.webp)

Leave a Reply

View Comments