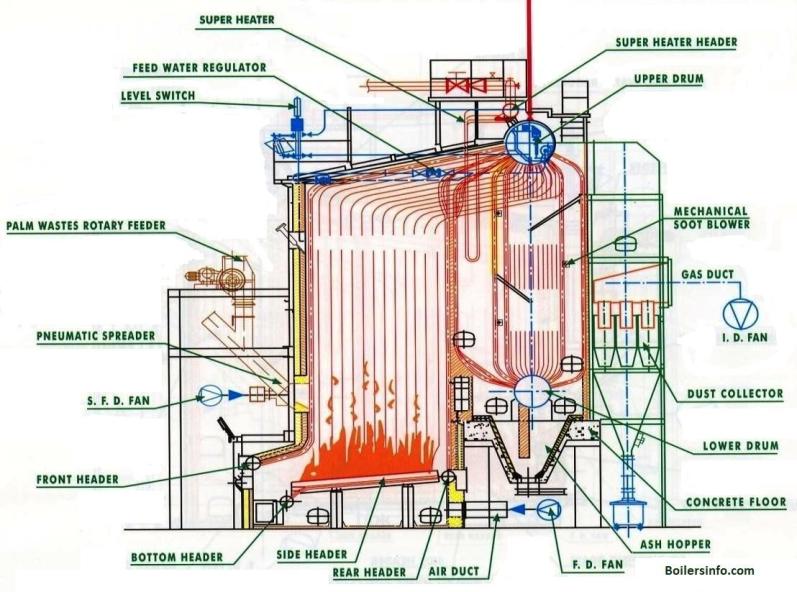

Low Water Level or Water Shortage — A water tube boiler is one of the vital components in various industrial sectors, such as power plants, chemical processing plants, oil refineries, and the food and beverage industry. This type of boiler is designed to produce high-pressure steam by heating water flowing inside small tubes, while the heat from fuel combustion flows around these tubes. Its high efficiency and ability to generate large volumes of steam make the water tube boiler the top choice for large-scale applications. However, behind its advantages, a water tube boiler also carries operational risks that must be closely monitored, one of which is the issue of low water level or a drop in water inside the boiler drum below the safe limit.

This condition frequently occurs due to system leaks, feedwater pump failure, or disturbances in the automatic control system. If not addressed promptly, low water level can trigger damage to boiler tubes due to overheating, reduce steam production efficiency, and, in the worst-case scenario, cause an explosion that endangers worker safety and damages production facilities. Therefore, in-depth knowledge of the causes, potential impacts, and preventive and corrective measures for low water level is crucial for boiler operators and technicians. This article will detail the factors that cause low water level, the resulting consequences, and practical solutions to maintain optimal and safe performance of water tube boilers in industrial settings.

Why Is Low Water Level Dangerous?

When the water level inside a boiler is too low, the tube walls are exposed to excessive heat without adequate cooling. This can lead to:

-

Overheating and material damage

-

Tube deformation and leakage

-

Boiler explosion if pressure is uncontrolled

Therefore, understanding how to prevent and handle this condition is essential for safety and operational efficiency.

Causes of Boiler Water Tube Low Water Level

Before finding solutions, it’s important to understand the causes. Here are some factors that trigger low water level:

1. Leakage in the Boiler System

Leaks within the boiler system are one of the main causes of undetected water loss. These leaks can occur in various parts, such as steam and water pipelines, flow control valves, and component joints. Small leaks often go unnoticed because the leaking water evaporates or seeps slowly, leaving no obvious puddles.

As a result, the water volume in the boiler drum continuously decreases, potentially causing overheating of the boiler tubes (water tubes) and decreased steam generation efficiency. To prevent this, routine inspections, pressure testing, joint maintenance, and timely replacement of worn seals must be carried out regularly.

2. Feedwater System Failure

Issues within the feedwater system often lead to low water levels in the boiler. This can happen due to several factors:

-

Feedwater pump malfunction: The pump may suffer mechanical damage, wear, or electrical power issues, making it unable to supply water to the boiler as needed. Reduced pump capacity causes slower water supply or a complete halt.

-

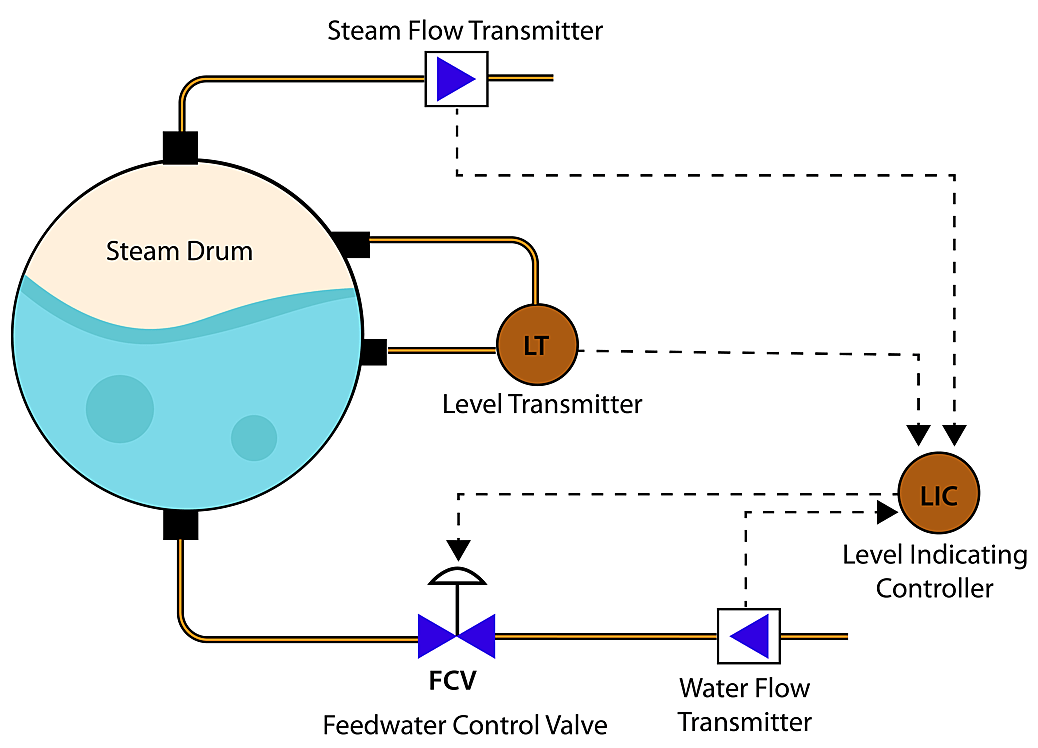

Automatic water level control failure: Many modern boilers use sensors and automatic controls to keep the water level stable. If the water level sensor is dirty, damaged, or improperly calibrated, the signal sent to the control valve or feedwater pump becomes inaccurate, resulting in improper water flow.

-

Operator errors in monitoring water level: Operators play a crucial role in verifying sensor readings and water level indicators. If operators neglect checking the water level or misread the indicator, necessary adjustments will be delayed, causing water shortage.

All these aspects are interrelated and require routine maintenance procedures and operator training to ensure the feedwater system functions optimally.

3. Sudden Increase in Steam Load

In some operational conditions, the steam demand from the system can surge suddenly, such as when multiple process equipment starts simultaneously or there is a sudden production need. This sudden steam load increase causes the water in the boiler drum to evaporate into steam more rapidly. If the feedwater system does not respond quickly enough or the pump cannot add water at the required rate, the water level will drop drastically in a short time.

This is highly dangerous as it can cause overheating of the boiler tubes, disrupt water circulation flow, and even pose explosion risks due to metal parts reaching excessive temperatures. Therefore, the boiler load control system must be designed to quickly adjust the feedwater supply in response to load fluctuations.

4. Boiler Water Contamination

Boiler feedwater must be kept pure through treatment processes to remove dissolved minerals and suspended particles. If water quality is neglected, mineral deposits (scaling) will form on the tube surfaces and water level sensors. Additionally, foaming caused by organic contamination or certain chemicals can cover the water surface. As a result, water level sensors — whether conductive, capacitive, or radar type — will give false readings because the signal is obstructed by deposits or foam.

Inaccurate water level readings will disrupt the feedwater control system and pose a risk of the boiler water dropping below safe limits. To prevent this, boiler water treatment must be consistently implemented, including regular testing of TDS (Total Dissolved Solids) content, alkalinity, and proper use of chemical dosing.

5. Control System Malfunction

The water level control system in a boiler is a vital component for maintaining safe and efficient operations. If the water level sensor suffers physical damage, is contaminated with deposits, or is not calibrated to the manufacturer’s standards, the data sent to the control panel or PLC will be incorrect. This causes the feedwater pump, control valve, or water level alarm to operate out of sync with the actual condition in the boiler drum.

For example, a miscalibrated sensor may detect a high water level when it is actually below the safe limit. As a result, no additional water is supplied, which can lead to serious boiler damage. Therefore, regular sensor inspection, calibration, and routine control circuit checks must be performed in accordance with standard operating procedures.

Effects of Low Water Level on Water Tube Boilers

The impacts caused by low water level or water shortage in a boiler include:

✅ Tube Material Damage

One of the most severe impacts is damage to the tube material, which serves as the circulation path for water and steam generation. When the water level drops below the minimum limit, the tube surfaces that should be submerged in water are directly exposed to high combustion heat. This condition causes the tube metal temperature to spike well above the material design limit. As a result, the metal’s mechanical properties weaken: the tube wall becomes brittle, loses structural strength, and undergoes permanent deformation such as bulging. If prolonged exposure continues, the tube can crack or burst, causing high-pressure steam leaks which are extremely dangerous.

✅ Reduced Boiler Efficiency

Low water level directly reduces boiler efficiency. When the drum has insufficient water, heat absorption is not optimal because the heat transfer area decreases. Most of the fuel’s energy is wasted through flue gas, which has a higher temperature than the design. Furthermore, if the tube is damaged by overheating, heat transfer performance worsens due to scaling or deformation. This forces the boiler to work harder with higher fuel consumption to produce the same amount of steam, significantly increasing operational costs.

✅ Explosion Hazard

The most severe danger of low water level is the risk of a boiler explosion. When the tube surfaces that should be submerged become dry, the metal temperature rises dramatically. If water suddenly re-enters (e.g., when the feedwater pump resumes operation), the contact between cold water and superheated metal can instantly generate a large volume of steam. This steam explosion causes a pressure spike inside the boiler drum that can exceed design limits. In the worst-case scenario, the drum or tubes rupture, releasing hot energy and metal fragments at high pressure, damaging surrounding structures and endangering workers’ safety. Therefore, protection systems and water level alarms must always be active and tested regularly.

✅ Production Downtime

Low water level in a water tube boiler almost certainly leads to costly production downtime. When damage occurs, the boiler must be shut down immediately to prevent further damage escalation. Repairs require careful steps, including cooling the unit, thorough inspection, replacing tubes or damaged components, and retesting to ensure safe operation. All these steps take time, skilled labor, and significant material costs. Meanwhile, a halted steam supply disrupts the main production process, reducing output, delaying delivery schedules, and ultimately impacting company revenue.

How to Handle Boiler Water Tube Low Water Level

-

Turn Off the Burner or Heat Source Immediately

The first step upon detecting low water level is to stop heating to prevent overheating. -

Check the Feedwater System

Ensure the feedwater pump is working properly.

Check if the water supply is blocked or not.

Verify the automatic water level control. -

Refill Water Carefully

Do not immediately add large amounts of water, as it may cause thermal shock. Refill gradually while monitoring pressure. -

Inspect for Leaks

Check pipes, valves, and joints.

Use a pressure test to detect hidden leaks. -

Recalibrate Water Level Sensors

Ensure high/low level sensors are working correctly. Clean off any scale or deposits that may affect accuracy. -

Use Alarm and Automatic Shutdown Systems

Install safety devices such as:

-

Low Water Cutoff (LWCO) → Shuts down the burner at critical water level.

-

Visual/audible alarm → Provides early warning.

-

Conduct Regular Maintenance

Perform regular blowdown to reduce deposits.

Check water quality (pH, hardness, dissolved oxygen).

Inspect boiler tubes periodically.

Preventing Low Water Level in the Future

-

Operator Training

Ensure operators understand:

-

How to read water levels correctly.

-

Emergency procedures in low water level conditions.

-

Install Real-Time Monitoring Systems

Use SCADA or IoT-based monitoring to track water level, pressure, and temperature in real time. -

Use Proper Water Treatment

Poor quality water causes scale and corrosion. Use:

-

Softener to reduce hard minerals.

-

Oxygen scavenger to prevent corrosion.

-

Store Backup Water Supply

Prepare emergency water supply in case the feedwater system fails.

Conclusion

Low Water Level or Water Shortage is a dangerous condition that can cause severe damage. By understanding its causes, impacts, and solutions, you can prevent significant losses. Routine maintenance, reliable control systems, and operator training are key to keeping boilers safe and efficient.

FAQ (Frequently Asked Questions)

Q: What should I do if the boiler runs out of water?

A: Immediately turn off the burner, do not add cold water at once, check for leaks, and refill gradually.

Q: How do I know if the boiler water level is too low?

A: Use a sight glass, level sensor, or automatic alarm.

Q: Can a boiler explode due to low water level?

A: Yes, because overheated tubes can rupture and cause a pressure explosion.

Q: What is the ideal frequency for boiler inspections?

A: Perform daily inspections, weekly maintenance, and annual overhauls.

By following these steps, the risk of low water level can be minimized, keeping boiler operations safe, efficient, and productive.