alwepo.com, Heavy Equipment Fleet Management Best Practices – In the construction and mining industries, managing a fleet of heavy equipment efficiently is crucial for maintaining productivity and profitability. Effective fleet management involves various practices, from regular maintenance and inspections to utilizing advanced technologies for tracking and optimizing performance. This comprehensive guide will delve into the best practices for managing heavy equipment fleets, helping businesses maximize their investments and ensure operational efficiency.

Understanding Heavy Equipment Fleet Management

Heavy equipment fleet management is a critical discipline within industries such as construction, mining, and logistics. It involves the comprehensive oversight and maintenance of a company’s heavy machinery and equipment to ensure they operate efficiently, safely, and cost-effectively. Given the high investment in heavy equipment, effective fleet management can significantly impact a company’s bottom line.

Importance of Effective Fleet Management

Effective fleet management is pivotal in industries relying heavily on machinery and equipment, such as construction, mining, and logistics. It involves a comprehensive approach to overseeing, maintaining, and optimizing the use of a company’s fleet to ensure operational efficiency, safety, and cost-effectiveness. Here are the key reasons why effective fleet management is crucial:

Cost Savings

One of the most significant benefits of effective fleet management is cost savings. Heavy equipment represents a substantial investment, and managing this investment efficiently can lead to considerable financial benefits.

- Preventive Maintenance: Regularly scheduled maintenance helps to identify and address potential issues before they become major problems. By performing routine inspections and servicing, companies can prevent costly breakdowns that can lead to expensive repairs and prolonged downtime.

- Extended Equipment Lifespan: Proper maintenance practices ensure that equipment remains in good working condition for a longer period. This reduces the need for frequent replacements, thereby maximizing the return on investment.

- Fuel Efficiency: Effective fleet management includes strategies to optimize fuel consumption, such as monitoring fuel usage, maintaining engines, and planning efficient routes. This helps in reducing fuel costs, which can be a significant portion of operating expenses.

- Inventory Management: Keeping an accurate inventory of parts and equipment allows for better purchasing decisions and prevents overstocking or stockouts, further reducing costs.

Productivity

Productivity is directly linked to the availability and reliability of equipment. Effective fleet management ensures that machinery is always ready to perform its required tasks, leading to uninterrupted operations and timely project completion.

- Reduced Downtime: Well-maintained equipment is less likely to experience unexpected failures. Scheduled maintenance and real-time monitoring help in identifying issues early, allowing for timely repairs and minimizing downtime.

- Optimal Utilization: Fleet management practices help in planning and scheduling equipment usage efficiently. This ensures that all machinery is utilized to its full potential, avoiding both underuse and overuse, which can lead to wear and tear.

- Streamlined Operations: Coordinating the movement and deployment of equipment through logistical planning ensures that machinery is at the right place at the right time, enhancing overall operational efficiency.

Safety

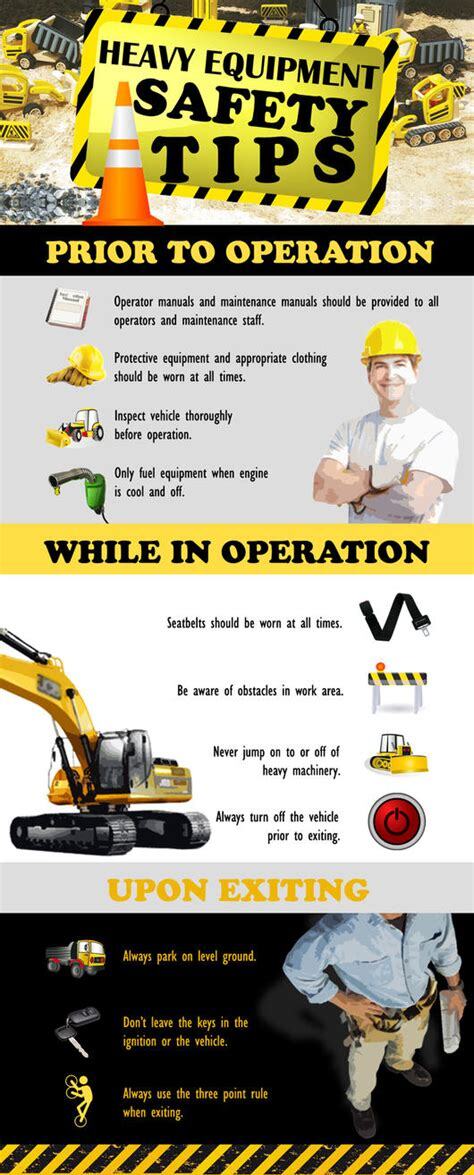

Safety is a paramount concern in industries that use heavy equipment. Proper fleet management practices significantly reduce the risk of accidents and injuries, ensuring a safer working environment for operators and other personnel.

- Maintenance and Inspections: Regular maintenance and thorough inspections ensure that equipment is in safe operating condition. This helps in identifying and fixing potential safety hazards before they cause accidents.

- Operator Training: Effective fleet management includes training programs for operators to ensure they are knowledgeable about the equipment they are using and are aware of safety protocols. Regular refresher courses help keep operators updated on best practices and new safety standards.

- Safety Protocols: Implementing and enforcing safety protocols, such as pre-operation checks and safe handling procedures, reduces the likelihood of accidents caused by operator error or equipment malfunction.

Compliance

Adhering to industry regulations and standards is essential to avoid legal issues and ensure the safety and reliability of operations. Effective fleet management helps in maintaining compliance with various regulatory requirements.

- Environmental Regulations: Managing equipment efficiently includes strategies to minimize environmental impact, such as reducing emissions and proper disposal of waste materials. Compliance with environmental regulations helps in avoiding fines and maintaining a good corporate reputation.

- Safety Standards: Regular maintenance and inspections ensure that all equipment meets safety standards set by industry regulators. This not only enhances safety but also helps in passing safety audits and inspections.

- Record Keeping: Effective fleet management involves maintaining detailed records of all maintenance activities, inspections, and compliance-related tasks. This documentation is crucial for demonstrating compliance during audits and regulatory checks.

Key Components of Fleet Management

Effective fleet management involves various interconnected components that work together to ensure the smooth operation, efficiency, and safety of a fleet of heavy equipment. These components include maintenance and repairs, asset tracking and monitoring, fuel management, and operator training and safety. Each component plays a crucial role in optimizing the performance and longevity of the equipment while minimizing operational costs and risks.

Maintenance and Repairs

Regular maintenance and timely repairs are the backbone of effective fleet management. They ensure that all equipment remains in optimal working condition, preventing unexpected breakdowns and extending the lifespan of the machinery.

- Scheduled Servicing: Routine maintenance based on a set schedule helps keep equipment in peak condition. This includes oil changes, filter replacements, lubrication of moving parts, and other preventive measures.

- Routine Inspections: Regular inspections allow for early detection of wear and tear or potential issues that could lead to equipment failure. This proactive approach helps in addressing problems before they escalate into major repairs.

- Timely Repairs: When issues are identified, addressing them promptly is essential to prevent further damage. Timely repairs minimize downtime and ensure that equipment is back in operation as quickly as possible.

- Maintenance Records: Keeping detailed records of all maintenance and repair activities helps in tracking the history of each piece of equipment. This data is invaluable for planning future maintenance, budgeting for repairs, and making informed decisions about equipment replacements or upgrades.

Asset Tracking and Monitoring

Asset tracking and monitoring involve using advanced technologies to keep a real-time check on the location, status, and performance of the equipment. This helps in managing the fleet more efficiently and ensuring that equipment is utilized effectively.

- GPS Tracking: Global Positioning System (GPS) technology allows for real-time tracking of equipment locations. This is crucial for managing large fleets spread across multiple sites, ensuring that equipment is where it needs to be and reducing the risk of theft or loss.

- Telematics: Telematics systems provide detailed data on equipment performance, including usage hours, fuel consumption, engine health, and other operational metrics. This information helps in making informed decisions about maintenance schedules, equipment utilization, and operational efficiency.

- Remote Monitoring: Advanced telematics and IoT (Internet of Things) devices enable remote monitoring of equipment. This allows fleet managers to track equipment status and performance from anywhere, facilitating quick responses to any issues that arise.

- Geofencing: Geofencing technology sets virtual boundaries around specific areas. When equipment enters or exits these boundaries, alerts are triggered, helping in managing equipment movements and preventing unauthorized usage.

Fuel Management

Fuel management is a critical aspect of fleet management, as fuel costs represent a significant portion of operating expenses. Effective fuel management strategies help control these costs and reduce the environmental impact of the fleet.

- Fuel Usage Monitoring: Tracking fuel consumption in real-time helps identify inefficiencies and areas for improvement. Telematics systems provide data on fuel usage, allowing for accurate monitoring and analysis.

- Route Optimization: Planning efficient routes reduces travel time and fuel consumption. By using GPS and route planning software, fleet managers can ensure that equipment takes the most efficient paths, minimizing unnecessary fuel usage.

- Regular Maintenance: Well-maintained equipment operates more efficiently, consuming less fuel. Regular servicing, such as engine tuning and air filter replacements, helps maintain optimal fuel efficiency.

- Fuel Management Systems: Dedicated fuel management systems track fuel purchases, usage, and storage. These systems help in preventing fuel theft, managing fuel inventory, and ensuring accurate fuel accounting.

Operator Training and Safety

Proper training for equipment operators is crucial for the safe and efficient operation of heavy machinery. Well-trained operators not only handle equipment more effectively but also contribute to overall safety and productivity.

- Equipment Handling Training: Operators need thorough training on the specific equipment they will be using. This includes understanding the controls, capabilities, and limitations of each piece of machinery.

- Safety Protocols: Training programs should emphasize safety protocols, including pre-operation checks, safe operating procedures, and emergency response measures. This helps in minimizing the risk of accidents and injuries.

- Regular Refresher Courses: Continuous training and refresher courses keep operators up-to-date with the latest best practices, safety standards, and technological advancements. This ensures that operators maintain a high level of competence and awareness.

- Certification and Compliance: Ensuring that operators are certified and comply with industry regulations is essential. Certification programs validate the operators’ skills and knowledge, contributing to overall fleet safety and regulatory compliance.

Best Practices for Heavy Equipment Fleet Management

Implementing a Preventive Maintenance Program

A preventive maintenance program involves regular inspections and servicing based on usage and time intervals. This proactive approach helps in identifying and addressing potential issues before they lead to equipment failure.

Steps to Implement a Preventive Maintenance Program:

- Schedule Regular Inspections: Set up a schedule for routine inspections and maintenance tasks.

- Use Checklists: Develop comprehensive checklists for each type of equipment to ensure all critical components are inspected.

- Keep Detailed Records: Maintain records of all maintenance activities, including dates, performed tasks, and any issues found.

- Monitor Equipment Usage: Use telematics to track equipment usage and adjust maintenance schedules accordingly.

Utilizing Fleet Management Software

Fleet management software helps streamline various aspects of fleet management, from maintenance scheduling to asset tracking and reporting. It provides real-time data and analytics, helping managers make informed decisions.

Benefits of Fleet Management Software:

- Centralized Data: Consolidates all fleet information in one place.

- Automated Scheduling: Automatically schedules maintenance and inspections.

- Real-Time Monitoring: Provides real-time updates on equipment status and location.

- Reporting and Analytics: Generates reports and analytics to track performance and identify areas for improvement.

Optimizing Equipment Utilization

Maximizing equipment utilization involves ensuring that all machinery is used efficiently and not left idle for long periods. This can be achieved through careful planning and scheduling.

Strategies to Optimize Equipment Utilization:

- Track Usage Patterns: Monitor equipment usage to identify underutilized machinery.

- Balance Workloads: Distribute workloads evenly across all available equipment.

- Schedule Smartly: Plan projects and tasks to make the best use of available machinery.

- Minimize Idle Time: Reduce idle time by coordinating tasks and equipment movements efficiently.

Managing Fuel Efficiency

Fuel costs are a significant part of operating expenses for heavy equipment fleets. Managing fuel efficiency involves monitoring fuel consumption and implementing practices to reduce fuel use.

Tips for Managing Fuel Efficiency:

- Regular Maintenance: Keep engines tuned and filters clean to ensure optimal fuel efficiency.

- Monitor Fuel Usage: Use telematics to track fuel consumption and identify inefficiencies.

- Optimize Routes: Plan routes to minimize travel time and fuel consumption.

- Train Operators: Educate operators on fuel-efficient driving techniques.

Ensuring Compliance with Regulations

Compliance with industry regulations and standards is crucial to avoid legal issues and ensure the safety of operations. This includes adhering to environmental regulations, safety standards, and other industry-specific requirements.

Steps to Ensure Compliance:

- Stay Informed: Keep up-to-date with the latest regulations and standards.

- Regular Audits: Conduct regular audits to ensure compliance with all regulations.

- Documentation: Maintain thorough documentation of all compliance-related activities.

- Training: Provide ongoing training to staff on regulatory requirements and best practices.

Advanced Technologies in Fleet Management

Telematics and GPS Tracking

Telematics and GPS tracking systems provide real-time data on equipment location, usage, and performance. These technologies help in optimizing routes, monitoring fuel consumption, and ensuring timely maintenance.

Predictive Maintenance

Predictive maintenance uses data analytics and machine learning to predict equipment failures before they occur. By analyzing data from sensors and other sources, predictive maintenance systems can identify patterns and predict when maintenance is needed.

AI and Machine Learning Applications

AI and machine learning can be used to analyze vast amounts of data and identify trends that can improve fleet management. These technologies can optimize maintenance schedules, predict equipment failures, and improve overall efficiency.

Challenges in Heavy Equipment Fleet Management

Managing a fleet of heavy equipment comes with several challenges, including:

- High Maintenance Costs: Keeping equipment in good working condition requires significant investment in maintenance and repairs.

- Complex Logistics: Coordinating the movement and usage of equipment across different sites can be complex and time-consuming.

- Safety Concerns: Ensuring the safety of operators and equipment is a constant challenge.

- Regulatory Compliance: Keeping up with changing regulations and ensuring compliance can be difficult.

Conclusion

Effective heavy equipment fleet management is essential for maximizing productivity, reducing costs, and ensuring the safety of operations. By implementing best practices such as preventive maintenance, utilizing advanced technologies, and managing fuel efficiency, businesses can optimize their fleet management processes. Staying informed about industry trends and continually improving fleet management strategies will help companies stay competitive and achieve long-term success.

This comprehensive guide covers the essential aspects of heavy equipment fleet management, providing practical insights and best practices to help businesses manage their fleets effectively. By following these guidelines, companies can ensure their heavy equipment operates efficiently, safely, and profitably.

Leave a Reply

View Comments