Hello alwepo readers, in this article, we will discuss “Off Highway Dump Truck.” The rumbling giants of the construction and mining industries, Off Highway Dump Trucks, have been instrumental in moving earth, rocks, and minerals for decades. These colossal machines are the unsung heroes behind the development of infrastructure and the extraction of valuable resources. In this article, we’ll dive deep into the world of Off Highway Dump Trucks, exploring their history, applications, technology, and future prospects.

The Mighty Off Highway Dump Truck

Understanding the Terminology

Before we delve into the fascinating world of Off Highway Dump Trucks, it’s essential to establish a clear understanding of the terminology associated with them.

Off Highway Dump Trucks: These are specialized vehicles meticulously designed for off-road usage, often in the harshest and most challenging terrains. Unlike their on-highway counterparts, which are primarily meant for smooth, paved roads, Off Highway Dump Trucks are engineered to thrive in environments where the conditions are anything but ideal.

In essence, these trucks are the rugged workhorses of industries such as mining, construction, and agriculture. They are the unsung heroes that navigate through unforgiving landscapes, ensuring that essential materials are transported efficiently and reliably.

The Evolution of Dump Trucks

The concept of dump trucks, including their precursor, the horse-drawn cart, can be traced back to the early 20th century. These early vehicles were relatively basic, operated manually, and had limited capabilities compared to their modern counterparts. However, they laid the foundation for a revolution in the transportation of bulk materials.

Over time, a series of remarkable technological advancements propelled dump trucks into the colossal machines we recognize today. These developments were driven by the growing demands of industries reliant on efficient material handling. As a result, dump trucks evolved from rudimentary conveyors of materials to the sophisticated workhorses that are integral to contemporary earthmoving operations.

The Modern-Day Giants

In the present day, Off Highway Dump Trucks stand as true engineering marvels. These behemoths are equipped with jaw-dropping features that distinguish them as giants in the world of heavy machinery.

Massive Payloads: One of the defining characteristics of modern Off Highway Dump Trucks is their colossal payload capacity. These trucks can carry vast amounts of materials, ranging from earth and rocks to minerals and construction aggregates. The payloads are measured in tons, often exceeding the capacities of several standard trucks combined.

Powerful Engines: To propel these mammoth loads, Off Highway Dump Trucks are equipped with powerful engines that produce an astounding amount of torque and horsepower. These engines are engineered to deliver consistent and reliable performance, even under extreme conditions.

Versatile Applications: Off Highway Dump Trucks are not confined to a single industry; they are versatile assets utilized across various sectors. They are indispensable in mining operations, where they transport extracted minerals and ores. In construction, they efficiently move massive quantities of materials like gravel, sand, and concrete. Additionally, they play a crucial role in the agricultural sector, aiding in tasks such as land preparation and crop transportation.

Terrain Dominance: What truly sets these modern giants apart is their ability to conquer challenging terrains with ease. They are purpose-built for off-road adventures, capable of navigating through rugged landscapes, steep inclines, and unpaved roads. This off-road prowess makes them ideal for industries that operate in remote and demanding locations.

Applications of Off Highway Dump Trucks

Mining Operations

The mining industry stands as one of the primary and most prominent domains for Off Highway Dump Trucks. Here’s a closer look at their role within this sector:

- Material Transport: Mining operations involve the extraction of valuable minerals, ores, and other geological resources from the earth. Off Highway Dump Trucks play a pivotal role in transporting these extracted materials within the mining site. They are responsible for moving everything from coal and iron ore to precious metals and minerals like copper and gold.

- High Payload Capacity: One of the key advantages of these trucks in mining is their exceptional payload capacity. They can carry massive quantities of materials in a single trip, significantly reducing the time and effort required for material handling.

- Efficiency and Productivity: Off Highway Dump Trucks contribute to the efficiency and productivity of mining operations. They ensure a steady flow of materials from the extraction point to processing or storage facilities. This reliability is crucial for meeting production targets and deadlines.

- Off-Road Performance: Mining sites are often situated in remote and challenging terrains. Off Highway Dump Trucks are purpose-built for these conditions, with the ability to navigate rough, unpaved roads and steep inclines. Their off-road capabilities ensure that mining activities can continue unhindered even in harsh environments.

Construction Sites

In the construction industry, Off Highway Dump Trucks are indispensable assets that facilitate the movement of essential materials. Here’s how they are applied in construction projects:

- Material Transportation: Construction sites require a constant supply of materials such as gravel, sand, crushed stone, and concrete. Off Highway Dump Trucks excel at transporting these bulk materials efficiently and in large quantities. This is particularly crucial for large-scale construction projects like highways, bridges, and skyscrapers.

- Reducing Labor and Time: By automating the process of material transport, Off Highway Dump Trucks reduce the need for manual labor and speed up construction timelines. This not only enhances efficiency but also minimizes costs associated with labor.

- Versatility: These trucks are versatile in their applications within construction. They can transport a wide range of construction materials, making them suitable for various phases of a project, from excavation to concrete pouring.

Agricultural Sector

The agricultural sector benefits from Off Highway Dump Trucks in several ways:

- Land Preparation: Before planting crops or establishing infrastructure on agricultural land, it often requires extensive preparation, including land grading and clearing. Off Highway Dump Trucks assist in these tasks by transporting earth and debris, making the land ready for cultivation or construction.

- Crop Transport: In large-scale farming, the need to transport harvested crops from the field to storage facilities or processing centers is paramount. Off Highway Dump Trucks are efficient in moving bulk quantities of crops like grain, fruits, and vegetables.

- Equipment Transport: Modern agriculture relies on heavy machinery like tractors and combines. Off Highway Dump Trucks are employed to transport these hefty pieces of equipment to different areas of the farm where they are needed, saving time and reducing wear and tear on the machinery.

The Parts of an Off Highway Dump Truck

An Off Highway Dump Truck is a complex piece of machinery, and each of its components plays a critical role in its overall function. Let’s explore these parts in detail:

Chassis

The chassis is the backbone of an Off Highway Dump Truck, providing the essential structural support for the entire vehicle. Here’s a closer look at its significance:

- Structural Integrity: The chassis is engineered to be incredibly robust and durable, as it must withstand immense loads and endure harsh conditions. These trucks often operate in challenging terrains, including rocky landscapes and uneven surfaces. The chassis’s structural integrity ensures that the truck can maintain stability and support its substantial payload.

- Frame Design: The chassis frame design varies among manufacturers but typically consists of a rugged frame structure made from high-strength steel. This frame serves as the foundation for mounting all other truck components, including the engine, transmission, axles, and dump body.

- Suspension Attachment: The suspension system, responsible for providing a smooth ride and maintaining traction on uneven terrain, is connected to the chassis. Proper attachment and integration of the suspension system are vital for the truck’s overall performance and operator comfort.

Engine

The engine is often regarded as the heart of an Off Highway Dump Truck, and for a good reason:

- Power Generation: Off Highway Dump Trucks are known for their ability to haul massive payloads efficiently. Achieving this requires an engine with substantial power output. These trucks are equipped with powerful engines that generate the immense torque and horsepower needed to propel the vehicle and its substantial load.

- Diesel Engines: Traditionally, these trucks have been powered by diesel engines due to their high torque and durability. Diesel engines are well-suited to the heavy-duty demands of Off Highway Dump Trucks, providing the necessary power for off-road operation.

- Electric and Hybrid Variants: In recent years, there has been a shift towards electric and hybrid Off Highway Dump Trucks as part of broader sustainability efforts. These alternative power sources aim to reduce emissions and operating costs while maintaining the performance required for heavy-duty applications.

Transmission

The transmission system in Off Highway Dump Trucks is specialized to handle the rugged terrains they traverse:

- Off-Road Performance: Off Highway Dump Trucks operate in off-road environments that often feature steep inclines, loose gravel, and challenging obstacles. The specialized transmission system is designed to provide optimal power delivery and traction in these conditions, ensuring the truck can navigate difficult terrains with ease.

- Transmission Types: These trucks may employ various transmission types, including automatic and manual transmissions. The choice of transmission depends on factors like the manufacturer’s design philosophy and the specific application of the truck. Automatic transmissions are favored for their ease of operation, while manual transmissions provide more control in certain situations.

Dump Body

The dump body is the functional core of an Off Highway Dump Truck, where materials are loaded and unloaded:

- Material Storage: The dump body is essentially a large container where materials, such as rocks, minerals, or earth, are stored during transportation. These materials are deposited into the dump body at the source and transported to the destination.

- Efficient Unloading: What sets the dump body apart is its ability to efficiently unload its contents. This is achieved through a hydraulic system that tilts or raises the dump body, allowing the materials to be discharged at the desired location. The efficiency of this process is vital for minimizing downtime and maximizing productivity.

- Design Considerations: The design of the dump body is carefully considered to ensure it can withstand the weight and impact of the materials it carries. It is typically made of high-strength steel and may feature reinforcement in critical areas to extend its lifespan.

Off Highway Dump Truck vs. Standard Dump Truck

Off Highway Dump Trucks and Standard Dump Trucks may share a common purpose, which is the transportation of materials, but they differ significantly in several key aspects. Let’s delve into the fundamental differences between these two types of dump trucks:

Design and Construction:

- Chassis and Suspension: Off Highway Dump Trucks are specifically designed to navigate rugged and uneven off-road terrains. They feature heavy-duty chassis and robust suspension systems that can absorb shocks and vibrations from rough surfaces. In contrast, Standard Dump Trucks are designed for on-road use and have lighter chassis and suspension systems suitable for smooth pavements.

- Tires: Off Highway Dump Trucks are equipped with large, deep-treaded, and sturdy tires designed to provide traction in off-road conditions. Standard Dump Trucks have thinner, road-focused tires that are not suited for challenging terrains.

- Frame Strength: Off Highway Dump Trucks have reinforced frames made from high-strength steel to withstand the stress of off-road operation. Standard Dump Trucks have frames optimized for highway use, making them lighter and less durable in off-road conditions.

Purpose:

- Off Highway Dump Trucks: These trucks are purpose-built for off-road applications, primarily in industries like mining, construction, and agriculture. They are meant to transport materials within rugged and remote job sites, where standard on-road vehicles would struggle.

- Standard Dump Trucks: These trucks are designed for on-road transportation of materials, typically within urban or suburban environments. They are commonly used for construction, municipal waste collection, and various transportation needs where smooth roads are available.

Payload Capacity:

- Off Highway Dump Trucks: These trucks are known for their enormous payload capacity. They can carry extremely heavy loads, often measured in tons, suitable for the demanding nature of off-road applications.

- Standard Dump Trucks: While Standard Dump Trucks can still carry substantial payloads, their capacity is generally lower than that of Off Highway Dump Trucks. They are ideal for tasks that require transportation within weight limits set by road regulations.

When to Choose Which:

Selecting the right type of dump truck for a job depends on several critical factors:

- Terrain: Off Highway Dump Trucks are the clear choice for jobs in rugged and challenging terrains, such as mining sites, quarries, and remote construction sites. Standard Dump Trucks are more suitable for urban or suburban environments with paved roads.

- Payload: Consider the weight of the materials to be transported. If you need to move extremely heavy materials, especially in off-road conditions, an Off Highway Dump Truck is the better choice due to its higher payload capacity.

- Distance: For short-distance transportation on smooth roads, Standard Dump Trucks are cost-effective and efficient. However, for longer hauls or off-road routes, Off Highway Dump Trucks are better equipped to handle the challenges.

- Regulations: Be aware of local regulations and road restrictions. Standard Dump Trucks may be subject to weight limits and size restrictions on certain roads, while Off Highway Dump Trucks can operate more freely in off-road areas.

- Operational Efficiency: Evaluate the overall efficiency of the project. Off Highway Dump Trucks are more productive in off-road settings, whereas Standard Dump Trucks excel in on-road applications.

The Unstoppable Engines

Off Highway Dump Trucks are renowned for their immense power, and the choice of engine technology is a critical factor in their performance and environmental impact. Let’s delve into the two primary engine technologies used in these trucks: Diesel Power and the Electric Revolution.

Diesel Power

Traditionally, Off Highway Dump Trucks have been equipped with diesel engines, and this choice comes with several noteworthy advantages:

- Durability: Diesel engines are renowned for their ruggedness and longevity. They are designed to withstand heavy loads, high temperatures, and the wear and tear that comes with off-road operation. This durability is crucial for trucks operating in demanding conditions such as mining sites and construction zones.

- High Torque: Diesel engines are known for their exceptional torque, which is essential for Off Highway Dump Trucks. Torque is the twisting force that allows these trucks to move heavy payloads and conquer challenging terrains. Diesel engines provide the robust torque needed for efficient hauling and off-road performance.

- Fuel Efficiency: Despite their high power output, diesel engines are relatively fuel-efficient. They can deliver more miles or kilometers per gallon of fuel compared to gasoline engines. This efficiency is beneficial for reducing operating costs, especially given the significant fuel consumption of these trucks.

- Availability of Diesel Fuel: Diesel fuel is widely available, making it a practical choice for industries that operate in remote or off-road locations. This availability ensures that these trucks can be refueled conveniently, even in areas with limited infrastructure.

However, diesel engines also have their downsides, primarily related to emissions and environmental concerns. They produce nitrogen oxides (NOx) and particulate matter, which can have adverse effects on air quality and contribute to global warming.

Electric Revolution

In recent years, the Off Highway Dump Truck industry has been undergoing a significant transformation with the introduction of electric powertrains. This Electric Revolution is driven by several compelling factors:

- Reduced Emissions: Electric dump trucks are touted for their potential to significantly reduce emissions. They produce no tailpipe emissions, making them an environmentally friendly alternative. This is particularly important in industries that are increasingly focused on sustainability and reducing their carbon footprint.

- Lower Operating Costs: Electric dump trucks have lower operating costs compared to their diesel counterparts. Electricity is often cheaper than diesel fuel, and electric trucks have fewer moving parts, resulting in reduced maintenance expenses. This translates into cost savings over the lifespan of the vehicle.

- Quieter Operation: Electric trucks operate more quietly than diesel-powered ones. This can be advantageous in environments where noise pollution is a concern, such as residential areas near construction sites or mining operations.

- Regenerative Braking: Electric trucks often feature regenerative braking systems, which recover energy during braking and convert it back into electricity. This can enhance overall efficiency and reduce energy waste.

The Hybrid Approach

In recent years, the heavy machinery industry, including manufacturers of Off Highway Dump Trucks, has been exploring innovative ways to make their vehicles more efficient, environmentally friendly, and cost-effective. One of the approaches gaining traction is the use of hybrid technology. This approach combines the best aspects of both electric and diesel power sources to create a more versatile and sustainable Off Highway Dump Truck. Let’s delve into the details of this hybrid approach:

1. Combining Electric and Diesel Power

- Electric Propulsion: The core of the hybrid approach is the integration of electric propulsion systems. These systems typically consist of electric motors powered by high-capacity batteries. Electric power provides several advantages, including instant torque for acceleration, reduced emissions, and quieter operation. Electric motors are known for their efficiency, making them an excellent choice for vehicles where energy conservation is crucial.

- Backup Diesel Generators: While electric propulsion is highly efficient, it may not always be practical for continuous operation over extended periods, especially in remote or resource-intensive industries like mining. To address this limitation, hybrid Off Highway Dump Trucks incorporate backup diesel generators. These generators serve as a secondary power source that can recharge the vehicle’s batteries or provide direct mechanical power to the wheels when needed.

2. Advantages of the Hybrid Approach

- Reduced Fuel Consumption: By incorporating electric propulsion, hybrid Off Highway Dump Trucks can significantly reduce fuel consumption compared to traditional diesel-powered counterparts. Electric power is particularly efficient in low-speed, high-torque applications, which are common in off-road and hauling scenarios.

- Lower Emissions: The reduced reliance on diesel power results in lower emissions of harmful pollutants like nitrogen oxides (NOx) and particulate matter (PM). This reduction aligns with environmental regulations and sustainability goals, making hybrid Off Highway Dump Trucks a more eco-friendly option.

- Energy Recovery: Hybrid systems often include regenerative braking, which converts kinetic energy into electrical energy when the vehicle slows down or descends slopes. This recovered energy can be stored in the batteries and used to assist in acceleration or to power auxiliary systems, further improving efficiency.

- Quiet Operation: Electric power provides a quieter operation compared to traditional diesel engines. This is beneficial for operators and reduces noise pollution in sensitive areas, such as residential neighborhoods near construction sites.

3. Flexibility in Operation

- Dual Power Sources: The hybrid approach offers flexibility in operation. These vehicles can run solely on electric power when noise and emissions need to be minimized, such as in urban construction sites. In more demanding conditions or during extended operations, the diesel generator can take over to provide continuous power.

- Improved Torque: Electric motors are known for their ability to deliver high torque at low speeds, which is particularly useful in off-road situations where vehicles often encounter rough terrain and steep inclines. This capability enhances the Off Highway Dump Truck’s performance and maneuverability.

4. Challenges and Considerations

- Battery Capacity: The capacity and durability of the batteries are critical factors in hybrid Off Highway Dump Trucks. Ensuring that the batteries can withstand the demanding conditions and provide adequate power is essential for reliable operation.

- Maintenance and Training: Operators and maintenance personnel may require additional training to understand and maintain hybrid systems effectively. Regular inspections and maintenance of both the electric and diesel components are crucial to ensure optimal performance.

- Initial Investment: Hybrid technology often comes at a higher initial cost compared to traditional diesel-powered vehicles. However, the long-term savings in fuel and reduced environmental impact can offset this initial investment.

Fuel Efficiency and Sustainability

Off Highway Dump Trucks have historically been perceived as heavy fuel consumers, earning them the stereotype of being “gas guzzlers.” However, the industry is undergoing a significant transformation, driven by the need for greater fuel efficiency and sustainability. Let’s explore in detail how this transformation is taking place:

1. Overcoming the Gas Guzzling Stereotype

- Historical Fuel Consumption: Off Highway Dump Trucks, due to their massive size and the demanding nature of their work, have indeed been heavy consumers of diesel fuel. The powerful engines required to move substantial payloads and navigate challenging terrains have contributed to this perception.

- Advancements in Engine Technology: In response to the need for improved fuel efficiency, manufacturers have made significant advancements in engine technology. These include more efficient combustion processes, better engine management systems, and the use of advanced materials to reduce weight.

- Transmission and Drivetrain Optimization: Efforts have been made to optimize transmission and drivetrain components to minimize energy losses during power transfer. This improves the overall energy efficiency of Off Highway Dump Trucks.

- Eco-Driving Practices: Operators are being trained in eco-driving practices, which involve techniques like smoother acceleration and braking to minimize fuel consumption. Proper maintenance and tire management also play a role in achieving better fuel efficiency.

2. Embracing Green Technologies

- Hydrogen Fuel Cells: Hydrogen fuel cell technology is gaining traction in the heavy machinery industry, including Off Highway Dump Trucks. Hydrogen fuel cells generate electricity through a chemical reaction between hydrogen and oxygen, producing only water vapor as a byproduct. This technology eliminates emissions of harmful pollutants and greenhouse gases, making it a green alternative to traditional diesel engines.

- Electric Drivetrains: Electric drivetrains are becoming increasingly popular, with some Off Highway Dump Trucks shifting from diesel engines to electric motors powered by high-capacity batteries. Electric drivetrains are highly efficient and produce zero tailpipe emissions. They are particularly well-suited for short-distance, high-torque applications common in mining and construction.

- Regenerative Braking: Many electric Off Highway Dump Trucks incorporate regenerative braking systems, which capture and store energy during braking or descending slopes. This recovered energy can be used to assist in acceleration, reducing the overall energy consumption of the vehicle.

3. Sustainable Mining Practices

- Environmental Impact: Mining operations have historically had significant environmental impacts, including habitat disruption and water pollution. The industry is increasingly focused on mitigating these effects through better practices.

- Reducing Emissions: Off Highway Dump Trucks are crucial in transporting extracted materials in mining operations. By transitioning to greener technologies, such as electric drivetrains or hydrogen fuel cells, these trucks can significantly reduce emissions, contributing to cleaner mining practices.

- Material Recycling: Another aspect of sustainability in mining is the recycling of materials. Some Off Highway Dump Trucks are designed to carry recyclable materials or even to be part of the recycling process by transporting and depositing materials in designated recycling facilities.

- Efficiency Improvements: Sustainable mining practices also involve optimizing operations for greater efficiency, reducing waste, and minimizing energy consumption. Off Highway Dump Trucks play a role in this by ensuring that materials are transported with minimal loss or waste.

Tackling the Toughest Terrains

Off Highway Dump Trucks are renowned for their ability to operate in some of the harshest and most challenging terrains on the planet. This capability is a defining feature of these vehicles and is essential for their successful deployment in industries like mining, construction, and agriculture. Let’s delve into the key aspects of their off-roading capabilities:

Off-Roading Capabilities

- Versatility in Terrain: One of the primary reasons Off Highway Dump Trucks are highly valued is their capacity to navigate a wide range of off-road terrains. These terrains may include rugged, uneven, and unpaved surfaces, as well as inclines, declines, and rocky landscapes. The ability to traverse such challenging conditions is crucial for industries that often operate in remote and less developed areas.

- Traction and Grip: Off-roading requires exceptional traction and grip to prevent slippage, especially when carrying heavy payloads. These trucks are typically equipped with specialized off-road tires that offer superior traction. Some models may even feature tire pressure control systems to optimize grip based on the terrain.

- Ground Clearance: Off Highway Dump Trucks are designed with substantial ground clearance to prevent obstacles like rocks and debris from hindering their progress. This high ground clearance allows them to overcome obstacles and navigate rough terrain without getting stuck or damaged.

- Stability: Maintaining stability while off-roading is critical, especially when carrying heavy loads. These trucks are engineered to provide stability through features like a low center of gravity, which reduces the risk of rollovers, and robust suspension systems that absorb shocks and vibrations.

All-Wheel Drive vs. Rear-Wheel Drive

Off Highway Dump Trucks are available in two primary drive configurations: all-wheel drive (AWD) and rear-wheel drive (RWD). The choice between these configurations depends on the specific application and terrain conditions:

- All-Wheel Drive (AWD): AWD Off Highway Dump Trucks are designed to provide power to all wheels simultaneously. This configuration offers superior traction and stability, making it well-suited for challenging off-road conditions. AWD is commonly chosen for mining and construction sites where the terrain can be unpredictable and demanding.

- Rear-Wheel Drive (RWD): RWD Off Highway Dump Trucks, on the other hand, provide power to the rear wheels only. While they may have less traction in some situations compared to AWD models, they are often more fuel-efficient and cost-effective. RWD trucks are sometimes preferred in applications where terrain conditions are relatively consistent and well-maintained.

Suspension Systems

Advanced suspension systems play a crucial role in ensuring the performance and durability of Off Highway Dump Trucks:

- Smooth Ride: Suspension systems are designed to absorb shocks and vibrations, providing a smoother and more comfortable ride for both the vehicle occupants and the cargo. This is especially important when transporting delicate materials or when operator comfort is a priority.

- Minimizing Wear and Tear: The suspension system’s ability to absorb shocks and impacts helps minimize wear and tear on the truck’s components, including the chassis, tires, and load-bearing structures. This extends the lifespan of the vehicle and reduces maintenance costs.

- Adjustable Suspension: Some modern Off Highway Dump Trucks feature adjustable suspension systems that can adapt to different terrains and loads. These systems allow operators to optimize the truck’s performance based on the specific conditions they are facing.

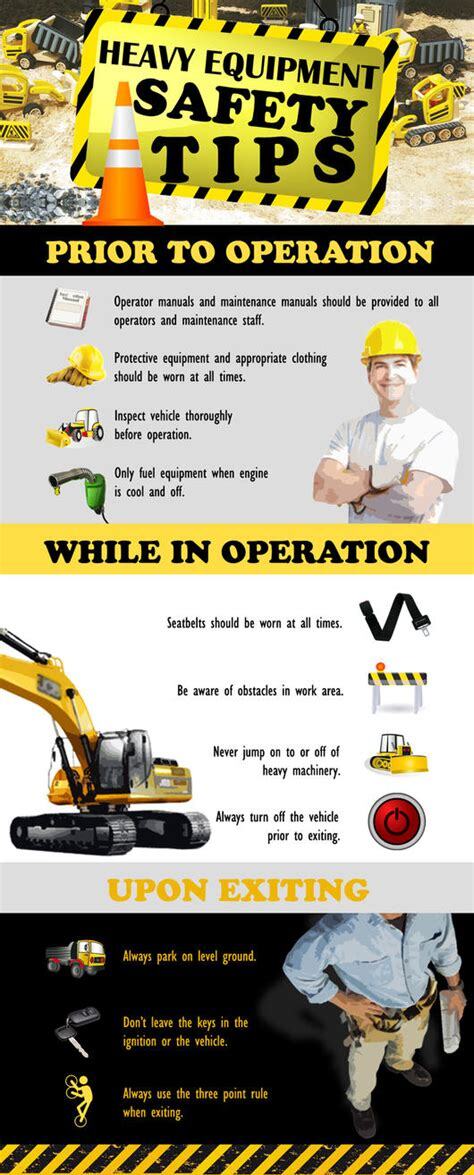

Safety Features

Ensuring the safety of both operators and workers in the vicinity of Off Highway Dump Trucks is a top priority for manufacturers and industries that rely on these heavy-duty vehicles. Let’s delve into the key safety features and measures that are implemented:

Roll-Over Protection

- Risks of Roll-Overs: Roll-over accidents pose a significant risk in industries where Off Highway Dump Trucks are used. These trucks often operate on uneven and challenging terrain, which can increase the likelihood of roll-over incidents, especially when carrying heavy payloads.

- Roll-Over Protection Systems (ROPS): To mitigate the risks associated with roll-overs, Off Highway Dump Trucks are equipped with specialized roll-over protection systems (ROPS). ROPS are engineered structures, often integrated into the vehicle’s cab, designed to prevent the roof from collapsing in the event of a roll-over. This protection ensures that the operator remains safe within the cab during such accidents.

- Rollover Warning Systems: Some modern Off Highway Dump Trucks are equipped with advanced roll-over warning systems. These systems utilize sensors and technology to monitor factors like vehicle stability and incline. When a potential roll-over situation is detected, the system alerts the operator, providing valuable seconds to take corrective action.

Collision Avoidance Systems

- Importance of Collision Avoidance: Accidents involving Off Highway Dump Trucks can have devastating consequences due to the vehicle’s size and weight. To prevent collisions, especially in busy work environments, collision avoidance systems have become increasingly important.

- Sensors and Cameras: Many modern Off Highway Dump Trucks are equipped with sensors and cameras that provide operators with real-time information about their surroundings. These systems detect obstacles, workers, or other vehicles in the vicinity and alert the operator to potential collisions.

- Automatic Braking: In some cases, collision avoidance systems can also include automatic braking features. If an imminent collision is detected and the operator does not respond, the system can apply the brakes to prevent or mitigate the impact.

Operator Training

- The Role of Training: Proper training is an integral part of ensuring the safe operation of Off Highway Dump Trucks. These vehicles require skilled and knowledgeable operators who can handle their power and navigate challenging terrains effectively.

- Training Programs: Many industries that utilize Off Highway Dump Trucks have established comprehensive training programs. These programs cover a range of topics, including vehicle operation, safety protocols, maintenance procedures, and emergency response.

- Certification and Licensing: In some regions, operators are required to obtain certification and licensing to operate Off Highway Dump Trucks legally. These certifications typically involve both classroom instruction and practical hands-on training.

- Safety Culture: Beyond technical training, fostering a safety culture within the workplace is essential. This includes promoting safe practices, encouraging open communication about safety concerns, and ensuring that all workers are aware of and adhere to safety guidelines.

Maintenance and Longevity

Ensuring the longevity and reliable performance of Off Highway Dump Trucks requires diligent maintenance practices and a keen understanding of the unique demands placed on these heavy-duty vehicles. Proper care not only extends their lifespan but also enhances safety and efficiency in the industries they serve.

Extending the Lifespan

Extending the lifespan of Off Highway Dump Trucks is a top priority for operators and fleet managers. Here’s how proper maintenance practices contribute to this goal:

Proper Maintenance Practices

- Preventive Maintenance: Preventive maintenance involves a proactive approach to servicing the trucks at regular intervals, regardless of their current condition. This includes tasks like oil changes, filter replacements, and inspections to identify potential issues before they escalate.

- Correct Lubrication: Proper lubrication of critical components, such as bearings, axles, and suspension parts, is crucial. Lubricants reduce friction and wear, prolonging the life of moving parts and preventing premature failure.

- Cleaning and Debris Removal: Regular cleaning of the dump body and undercarriage helps prevent the buildup of dirt, rocks, and debris that can lead to corrosion and mechanical stress. Cleaning also improves the efficiency of components like radiators and cooling systems.

- Tire Maintenance: Tire maintenance is especially vital for Off Highway Dump Trucks because they often operate on abrasive surfaces. Regular tire inspections, pressure checks, and rotations ensure even wear and prolong tire life.

- Electrical System Checks: Monitoring the electrical system, including batteries, wiring, and connectors, is essential. Weak or corroded electrical connections can cause downtime and affect the truck’s performance.

Routine Inspections

- Visual Inspections: Daily or pre-operational visual inspections help operators identify obvious issues such as leaks, loose components, or visible damage. Early detection allows for prompt repairs.

- Scheduled Inspections: Periodic scheduled inspections conducted by qualified technicians are more comprehensive. They include in-depth checks of critical systems like brakes, steering, hydraulics, and engine performance.

Overhauls and Replacements

- Engine Overhauls: Over time, even well-maintained engines may require overhauls to address wear and tear. This involves disassembling the engine, replacing worn components, and reassembling it to restore performance.

- Transmission and Axle Rebuilds: The transmission and axles, which endure heavy loads and stress, may also need periodic rebuilds. This process involves disassembling these components, replacing worn parts, and ensuring proper alignment and lubrication.

- Component Replacement: Beyond overhauls, Off Highway Dump Trucks may require component replacements, such as hydraulic system components, suspension parts, and exhaust systems. These replacements are essential for maintaining safety and efficiency.

- Dump Body Maintenance: The dump body, subjected to constant loading and unloading, may require refurbishment or replacement over time. Ensuring its structural integrity is vital for safety and efficiency.

Properly timed overhauls and component replacements are critical to avoiding major breakdowns and minimizing downtime. These procedures should follow manufacturer-recommended maintenance schedules and consider factors like hours of operation and operating conditions.

Global Market Overview

The market for Off Highway Dump Trucks is a dynamic and competitive landscape. To gain a comprehensive understanding, it’s essential to examine the leading manufacturers and the regional variations that influence the popularity of specific brands and types of dump trucks.

Leading Manufacturers

In the realm of Off Highway Dump Trucks, several manufacturers stand out as key players, each renowned for its unique contributions to the industry. Here’s an overview of some of the leading manufacturers:

- Caterpillar Inc.: Caterpillar, often referred to simply as Cat, is one of the most recognized names in the heavy equipment industry. They offer a wide range of Off Highway Dump Trucks known for their durability, performance, and advanced technology.

- Komatsu Ltd.: Komatsu is a global giant in construction and mining equipment, including Off Highway Dump Trucks. Their vehicles are prized for their innovation, fuel efficiency, and operator comfort.

- Volvo Group: Volvo’s articulated dump trucks are esteemed for their robustness and high-tech features. They have a strong presence in the Off Highway Dump Truck market, offering a variety of models tailored to different applications.

- Liebherr Group: Liebherr is known for producing Off Highway Dump Trucks that excel in both performance and safety. Their machines are often employed in demanding environments like mining and quarrying.

- Hitachi Construction Machinery Co.: Hitachi is recognized for its powerful and reliable dump trucks. Their models are popular in various industries, including construction, mining, and material handling.

- Terex Corporation: Terex is known for its wide range of construction and mining equipment, including rigid and articulated dump trucks. They prioritize durability and ease of maintenance in their designs.

Regional Dominance

While these leading manufacturers have a global presence, the popularity of specific brands and types of dump trucks can vary significantly by region. Several factors contribute to this regional variation:

- Terrain: The geographical features and terrain of a region heavily influence the choice of dump truck. For instance, hilly or mountainous areas may favor articulated dump trucks due to their superior maneuverability on uneven terrain.

- Industry Specialization: Certain regions are more focused on specific industries. For example, areas with extensive mining operations may have a higher demand for larger rigid dump trucks capable of carrying substantial payloads.

- Local Preferences: Regional preferences also play a role. Local operators and businesses often have loyalty to specific brands or manufacturers based on their experiences with reliability and support.

- Regulations and Emissions Standards: Environmental regulations and emissions standards can differ by region. Some areas may favor dump trucks with advanced emission control systems to meet stringent environmental requirements.

- Economic Factors: Economic conditions within a region can influence the type and size of dump trucks in demand. Booming construction or mining industries may lead to increased sales of larger, more powerful trucks.

Innovations in Dump Truck Technology

Dump trucks, especially Off Highway Dump Trucks, have seen significant technological advancements in recent years. These innovations are transforming the industry, enhancing safety, efficiency, and sustainability. Let’s explore some of the notable innovations in dump truck technology:

Autonomous Dump Trucks

- Enhancing Safety and Efficiency: Autonomous dump trucks represent a cutting-edge development in the industry. These vehicles are equipped with advanced sensors, cameras, and artificial intelligence systems that enable them to operate without direct human intervention. This innovation is primarily aimed at enhancing safety by reducing the risk of accidents caused by human error, such as fatigue or distraction.

- Reducing Labor Costs: Autonomous dump trucks have the potential to significantly reduce labor costs associated with manual truck operation. These vehicles can operate 24/7, increasing productivity and efficiency on job sites.

- Precise Navigation: Autonomous dump trucks rely on GPS technology and advanced mapping systems to navigate precisely. They can follow predefined routes and avoid obstacles, making them ideal for repetitive tasks in controlled environments like mines and construction sites.

- Real-Time Data Collection: These trucks continuously collect data on their performance and surroundings, which can be invaluable for monitoring productivity, identifying maintenance needs, and optimizing operations.

- Challenges and Adoption: While the promise of autonomous dump trucks is substantial, there are challenges to overcome, including regulatory hurdles, safety concerns, and the need for substantial upfront investment. However, as technology continues to advance and prove its value, the adoption of autonomous dump trucks is expected to grow.

Advanced Telematics

- Real-Time Data and Connectivity: Telematics systems are revolutionizing the dump truck industry by providing real-time data on vehicle performance and health. These systems use sensors and GPS technology to collect data on various parameters, including engine performance, fuel consumption, location, and even driver behavior.

- Maintenance Optimization: Telematics data enables predictive maintenance, which means that issues can be identified and addressed before they lead to breakdowns. This not only reduces downtime but also extends the lifespan of dump trucks.

- Route Optimization: Telematics systems can analyze traffic patterns and road conditions to suggest optimal routes for dump trucks. This reduces fuel consumption, minimizes wear and tear, and improves delivery times.

- Enhanced Safety: Telematics can also monitor driver behavior, including speeding and harsh braking. This data can be used to improve driver safety and reduce accidents.

- Remote Monitoring: Fleet managers can remotely monitor their dump trucks in real-time, allowing them to make informed decisions about route changes, maintenance scheduling, and fuel efficiency improvements.

Artificial Intelligence Integration

- Route Optimization: Artificial intelligence (AI) is being used to optimize dump truck routes based on real-time data. AI algorithms analyze traffic patterns, weather conditions, and other variables to determine the fastest and most efficient routes, reducing fuel consumption and delivery times.

- Predictive Maintenance: AI can predict when dump trucks will require maintenance based on data from sensors and telematics systems. This allows for proactive maintenance scheduling, preventing costly breakdowns and extending the life of the trucks.

- Fuel Efficiency: AI is used to optimize fuel efficiency by adjusting engine performance based on real-time data. This includes adjusting engine power and transmission settings to reduce fuel consumption while maintaining performance.

- Load Optimization: AI algorithms can determine the optimal load for each dump truck based on the type of material being transported and the truck’s capacity. This ensures that trucks are operating at maximum efficiency and safety.

- Safety Enhancements: AI can also contribute to safety by assisting with features like collision avoidance systems, driver monitoring, and adaptive cruise control.

Cost Analysis

Analyzing the costs associated with Off Highway Dump Trucks is a critical aspect of decision-making for industries that rely on these heavy-duty vehicles. Here’s a detailed breakdown of cost analysis, encompassing the initial investment, operational costs, and long-term value:

Initial Investment

- Purchase Price: The most apparent cost is the purchase price of the Off Highway Dump Truck. These trucks are significant capital investments, and the price can vary widely depending on factors such as payload capacity, brand, model, and optional features. Fleet managers and operators must assess their budget and operational requirements to select the right truck within their financial constraints.

- Customization: Depending on the specific needs of the industry, customization may be necessary. This includes adding specialized equipment, adapting the truck for certain applications, or integrating safety features. Customization can significantly impact the initial investment.

- Financing and Interest Rates: Many businesses opt to finance the purchase of Off Highway Dump Trucks rather than paying the entire amount upfront. Understanding the financing terms, interest rates, and the total cost of financing is crucial for evaluating the true initial investment.

Operational Costs

- Fuel Expenses: Fuel costs are a significant part of the operational expenses for Off Highway Dump Trucks. These trucks often have large diesel engines that consume substantial quantities of fuel. Fuel prices, fuel efficiency, and the distance traveled all impact this cost. Fuel efficiency can be improved with proper maintenance and operational practices.

- Maintenance and Repairs: Maintenance expenses include routine tasks such as oil changes, filter replacements, and tire maintenance. However, Off Highway Dump Trucks also require periodic overhauls and component replacements. These maintenance costs vary depending on the truck’s age, usage, and maintenance practices.

- Labor Costs: Labor expenses encompass the salaries and benefits of operators, mechanics, and maintenance personnel. Skilled operators are essential for efficient and safe truck operation. Proper training and retaining experienced operators can help optimize labor costs.

- Tire Costs: Off Highway Dump Trucks rely on robust, specialized tires designed for off-road conditions. These tires can be expensive and require frequent inspections, rotations, and replacements due to the challenging terrains these trucks navigate.

Long-Term Value

- Resale Value: Consideration of the long-term value is crucial. Off Highway Dump Trucks typically have a long operational life, and their resale value can significantly impact the total cost of ownership. Resale value depends on factors like maintenance history, age, and condition.

- Depreciation: Off Highway Dump Trucks depreciate over time, which affects their long-term value. Understanding the depreciation rate and planning for potential losses in asset value is essential.

- Total Cost of Ownership (TCO): TCO is the cumulative cost of owning and operating an Off Highway Dump Truck over its entire lifespan. It includes the initial purchase price, operational expenses, maintenance costs, and resale value. Assessing the TCO provides a comprehensive view of the financial implications of owning these vehicles.

- Asset Utilization: Maximizing the utilization of Off Highway Dump Trucks is essential for optimizing long-term value. Ensuring that the trucks are in operation for a significant portion of their lifespan and that they are not underutilized is critical for achieving a favorable return on investment.

Renting vs. Buying

Deciding whether to rent or buy Off Highway Dump Trucks is a critical choice that businesses in industries like mining, construction, and agriculture must make. Each option has its own set of advantages and disadvantages, and the decision ultimately depends on the specific needs and financial circumstances of the business. Let’s delve into the pros and cons of renting and buying Off Highway Dump Trucks, as well as the key decision factors:

Pros and Cons

Renting Off Highway Dump Trucks

Pros:

- Flexibility: Renting provides flexibility, allowing businesses to scale their fleet up or down based on project requirements. It’s ideal for short-term or intermittent needs.

- Lower Initial Costs: Renting requires less upfront capital compared to purchasing. Businesses can allocate their financial resources elsewhere.

- Maintenance Included: In many rental agreements, maintenance and repairs are included. This can reduce downtime and operational headaches.

- Access to New Equipment: Renting often gives access to the latest models and technology, which can improve efficiency and productivity.

Cons:

- Higher Long-Term Costs: While the upfront costs are lower, the cumulative expenses of renting over an extended period can surpass the cost of buying.

- No Ownership: Renting means the business does not own the equipment, so there’s no potential for asset appreciation or resale value.

- Limited Customization: Rental equipment may not be customized to specific project needs, limiting versatility.

Buying Off Highway Dump Trucks

Pros:

- Ownership: Buying provides full ownership of the equipment, which can be an asset on the balance sheet and have resale value.

- Long-Term Cost Efficiency: Over time, buying can be more cost-effective than renting, especially for businesses with ongoing and frequent needs for Off Highway Dump Trucks.

- Customization: Buyers can customize the equipment to their specific requirements, enhancing productivity and versatility.

Cons:

- Higher Initial Costs: Purchasing requires a significant upfront investment, which may strain a business’s capital resources.

- Maintenance Costs: Buyers are responsible for maintenance and repair costs, which can be unpredictable and costly.

- Depreciation: Equipment ownership comes with depreciation, which reduces the asset’s book value over time.

Decision Factors

Several factors influence the decision between renting and buying Off Highway Dump Trucks:

- Project Duration: Short-term projects with no long-term need may favor renting, while ongoing or frequent projects may justify purchasing.

- Frequency of Use: Businesses with intermittent use may find renting more cost-effective, whereas those with constant demand may benefit from ownership.

- Financial Resources: The availability of capital plays a significant role. If a business has ample capital, buying may be a viable option. Conversely, businesses with limited capital may opt for renting to conserve funds for other investments.

- Customization Needs: Projects with unique requirements that demand specialized equipment may lean towards purchasing for customization options.

- Maintenance Capability: Businesses with the in-house capacity for maintenance and repairs may find buying more attractive, while others may prefer renting with maintenance services included.

- Resale Value: Consider whether the equipment will have residual value. If there’s potential for resale, buying becomes more appealing.

- Tax Considerations: Consult with financial advisors to understand tax implications, as both renting and buying can have tax advantages or disadvantages depending on local regulations.

Environmental Impact

Off Highway Dump Trucks are powerful workhorses of various industries, but their operations can have significant environmental consequences. Recognizing these impacts, there are concerted efforts to mitigate them, focusing on emissions control, biodiesel adoption, and recycling.

Emissions Control

Controlling emissions from Off Highway Dump Trucks is a priority to reduce their environmental footprint.

- Emission Sources: Off Highway Dump Trucks, particularly those powered by diesel engines, emit various pollutants during their operations. These include nitrogen oxides (NOx), particulate matter (PM), carbon monoxide (CO), and hydrocarbons (HC), all of which contribute to air pollution and negative health effects.

- Emissions Regulations: Environmental agencies and governments worldwide have imposed stringent emissions regulations on heavy-duty vehicles, including Off Highway Dump Trucks. These regulations set limits on emissions and require manufacturers to develop and implement technologies to meet these standards.

- Emission Reduction Technologies: To comply with emissions regulations, manufacturers have incorporated technologies such as selective catalytic reduction (SCR), diesel particulate filters (DPF), and exhaust gas recirculation (EGR). These systems reduce harmful emissions by converting pollutants into less harmful substances or capturing them.

- Hybrid and Electric Options: Some manufacturers are exploring the use of hybrid and electric powertrains in Off Highway Dump Trucks to achieve zero-emission operation. Electric and hybrid models have the potential to significantly reduce or eliminate on-site emissions and noise pollution.

Biodiesel Adoption

The adoption of biodiesel fuels is one way the industry is striving to reduce its carbon footprint.

- Biodiesel Basics: Biodiesel is a renewable fuel made from biological sources, such as vegetable oils, animal fats, or algae. It is considered a more environmentally friendly alternative to traditional diesel fuel because it produces fewer greenhouse gas emissions.

- Blends and Compatibility: Biodiesel can be used as a blend with conventional diesel fuel (e.g., B5, B20) or as a pure biodiesel (B100). Many Off Highway Dump Trucks are compatible with biodiesel blends, allowing for an easy transition to a more sustainable fuel source.

- Emissions Reduction: Biodiesel has lower levels of sulfur and aromatics than conventional diesel fuel, which can result in reduced emissions of sulfur dioxide (SO2) and particulate matter. It also has a higher cetane rating, contributing to improved combustion efficiency and lower CO and HC emissions.

- Lifecycle Analysis: Biodiesel’s environmental benefits extend to its lifecycle analysis, considering its production, use, and end-of-life stages. It often has a lower carbon footprint compared to conventional diesel, especially when produced from sustainable feedstocks.

Recycling Efforts

Efforts to recycle materials and components from retired dump trucks contribute to sustainability.

- Retired Dump Trucks: As Off Highway Dump Trucks age or reach the end of their operational life, they are often retired from service. Recycling efforts focus on reusing and repurposing components and materials from these retired vehicles.

- Component Reuse: Components like engines, transmissions, axles, and hydraulics can often be refurbished and reused in other equipment or vehicles, reducing the need for new manufacturing and conserving resources.

- Material Recycling: Scrap metal from retired dump trucks can be recycled to produce new materials, reducing the demand for raw resources and minimizing waste sent to landfills.

- Environmental Benefits: Recycling efforts contribute to resource conservation, energy savings, and reduced environmental impact. They align with the principles of circular economy and sustainability.

The Future of Off Highway Dump Trucks

The future of Off Highway Dump Trucks promises significant advancements driven by a combination of environmental concerns, technological innovations, and sustainability imperatives. Let’s delve into the key developments shaping the future of these heavy-duty vehicles:

Going Electric

The shift towards electric Off Highway Dump Trucks is expected to accelerate as the industry pursues greener solutions.

- Environmental Imperatives: Concerns about air quality, carbon emissions, and sustainability have led the industry to explore electric propulsion as a cleaner alternative to traditional diesel engines. Electric vehicles (EVs) produce zero tailpipe emissions, reducing their environmental impact.

- Battery Technology: Advances in battery technology are enabling the development of high-capacity, long-lasting batteries suitable for heavy machinery like Off Highway Dump Trucks. These batteries can store enough energy to power the trucks through long shifts, making electric trucks increasingly practical.

- Reduced Operating Costs: Electric vehicles have lower operating costs compared to diesel-powered counterparts. They require less maintenance, have fewer moving parts, and are often more energy-efficient, resulting in long-term cost savings.

- Noise Reduction: Electric trucks operate more quietly than their diesel counterparts, reducing noise pollution in sensitive areas and improving the working environment for operators.

- Infrastructure Development: To support the widespread adoption of electric Off Highway Dump Trucks, infrastructure for charging and energy storage will need to expand. This includes on-site charging stations at mining and construction sites.

Automation and AI

Automation and AI technologies will continue to evolve, making these trucks safer and more efficient.

- Safety Improvements: Automation and AI systems can enhance safety by assisting operators in navigating challenging terrains, avoiding obstacles, and preventing accidents. These technologies can provide real-time feedback and alerts to operators.

- Efficiency Enhancement: AI-driven systems can optimize route planning, load distribution, and speed control, leading to more efficient operations. Autonomous features can help maintain consistent speeds and minimize fuel or energy consumption.

- Remote Operation: The development of remote control and autonomous operation capabilities allows operators to control and monitor Off Highway Dump Trucks from a safe distance. This can be particularly valuable in hazardous or remote environments.

- Data Analytics: AI can analyze vast amounts of data generated by these trucks to identify trends, predict maintenance needs, and optimize performance. This data-driven approach can lead to cost savings and increased productivity.

Sustainable Practices

Sustainability will remain at the forefront of industry initiatives, with Off Highway Dump Trucks playing a pivotal role.

- Emissions Reduction: The industry will continue to focus on reducing emissions through technologies like electrification, alternative fuels, and emissions control systems. Stricter emissions regulations will drive innovation in this area.

- Recycling and Circular Economy: Sustainability efforts will extend to the end-of-life phase of Off Highway Dump Trucks. Recycling materials and components will become standard practice, reducing waste and conserving resources.

- Eco-Friendly Materials: The use of sustainable and eco-friendly materials in manufacturing will gain prominence. Lightweight materials, bio-based plastics, and recyclable components will be favored for their environmental benefits.

- Efficiency and Productivity: Sustainable practices will also include efforts to maximize the efficiency and productivity of these trucks. This involves reducing idle time, optimizing routes, and minimizing energy consumption.

Conclusion

In conclusion, Off Highway Dump Trucks are the workhorses of industries that shape our world. They have come a long way from their humble beginnings and are now at the forefront of technological innovation. As they continue to evolve, their impact on construction, mining, and other sectors will only grow. The future promises greener, more efficient, and safer Off Highway Dump Trucks, contributing to a sustainable and prosperous world.

Thus the article about Off Highway Dump Truck. Feel free to share your thoughts and continue the discussion in the comments section, don’t forget to share the article with your friends or your favorite social media. Hope it is useful!

Leave a Reply

View Comments