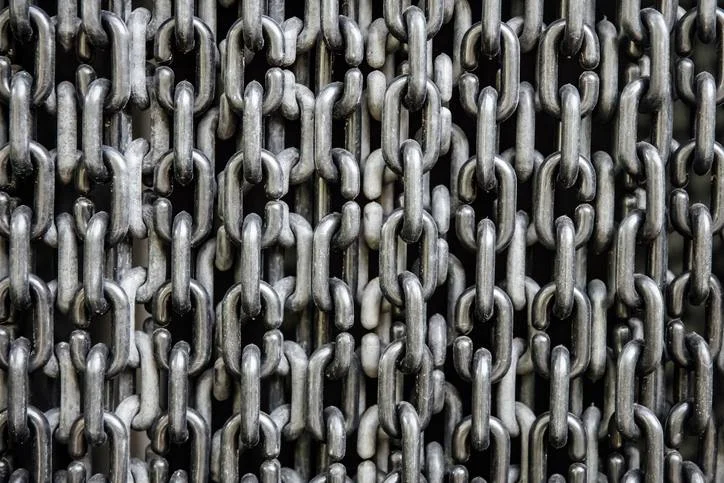

alwepo, Steel chains are essential components in various industries, including manufacturing, construction, mining, and logistics. The production process of steel chains involves several complex stages to create end products that are strong, durable, and meet high-quality standards. Here is a general overview of the steel chain production process:

1. Raw Material Preparation

The process begins with the selection of high-quality raw materials. The steel used must meet specific strength standards to ensure that the chain has the required strength and durability. The raw material typically consists of steel coils that will be used in the subsequent stages.

2. Steel Cutting

Steel coils are cut to the appropriate length for the size of the chain to be produced. Cutting can be done using automated cutting machines to ensure size accuracy and precision.

3. Heating and Chain Link Forming

The next step involves heating the ends of the steel that will form the chain links. Heating is done to facilitate the pressing process. After heating, the heated steel ends are placed in a molding machine that shapes them into chain links with the desired form.

4. Handle Link Forming

In addition to chain links, chains also have handles that allow them to be held or connected to other tools. Chain handles are usually placed in the middle of the chain and are also formed through a molding process similar to chain links.

5. Rolling and Formation

Once the chain links and handles are formed, the chain is then run through rolling machines to form a complete chain loop. At this stage, the chain may also undergo further heating to eliminate internal stress that can occur during formation.

6. Hardening and Strengthening

The chain then undergoes a hardening process to enhance its strength. This can involve heating and rapid cooling (quenching) in specialized cooling media. The hardening process is followed by a tempering process to reduce the brittleness that may result from hardening.

7. Quality Testing

After the chain is fully formed, it undergoes a series of quality tests to ensure that the product meets the established standards. Testing includes strength testing, surface quality testing, and visual inspections.

8. Coating or Protection

Some steel chains may need to be coated with protective layers, such as anti-corrosion coatings, to enhance their lifespan in harsh environmental conditions.

9. Packaging and Distribution

After passing quality testing, the steel chain is ready to be securely packaged and distributed to the market. Chains are produced in various sizes and capacities to meet the needs of different industries.

In the modern industry, technology and automation have contributed to efficiency and precision in the steel chain production process. With careful stages and rigorous quality testing, the produced steel chains have the expected quality and are ready for use in various industrial applications.

Leave a Reply

View Comments